PAVIPLAST® W A+B

Formulato epossidico autolivellante in emulsione acquosa

Formulato epossidico bicomponente colorato a base acqua. Autolivellante per realizzare pavimentazioni industriali in interni. Aspetto opaco.

Tipologia: Formulati Epossidici a Base Acquosa

Descrizione

Prodotto bicomponente a base di resine epossidiche e indurenti amminici cicloalifatici.

Consente di ottenere rivestimenti con alte resistenze meccaniche e ottime caratteristiche di permeabilità.

L’aspetto è opaco, finemente antisdrucciolevole.

Utilizzi

Pavimentazioni in interno di industrie meccaniche, alimentari e chimiche, di depositi e magazzini, di laboratori ed ospedali, di negozi, showroom ed appartamenti.

Supporto

Il sottofondo deve possedere una resistenza minima alla compressione di 25 N/mm2 e a trazione di 1,5 N/mm2.

Preparazione del supporto

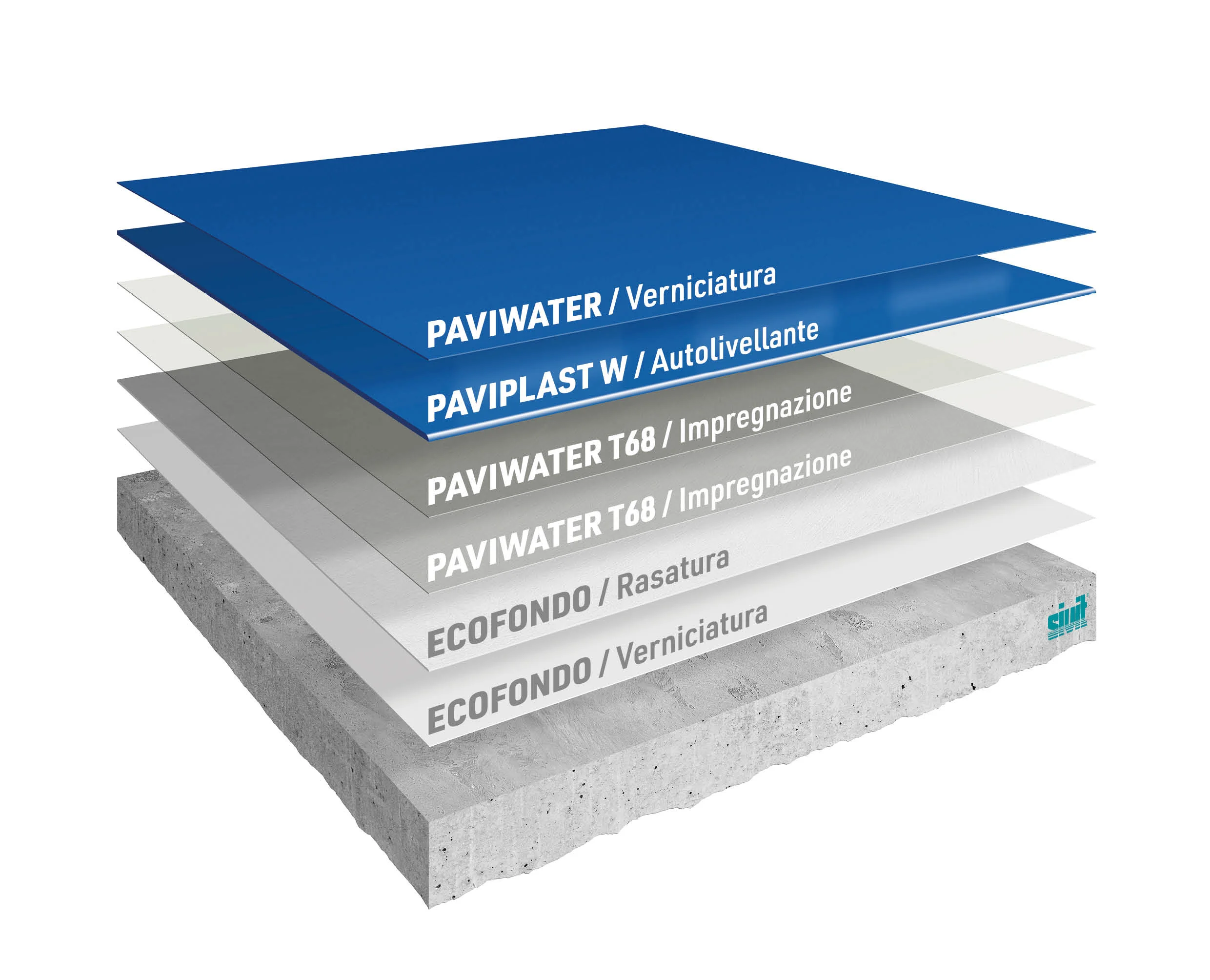

Fondi in cls dovranno essere solidi, asciutti (stagionati se di nuova costruzione), livellati, assorbenti, non inquinati da oli, detergenti, polveri od altre sostanze.

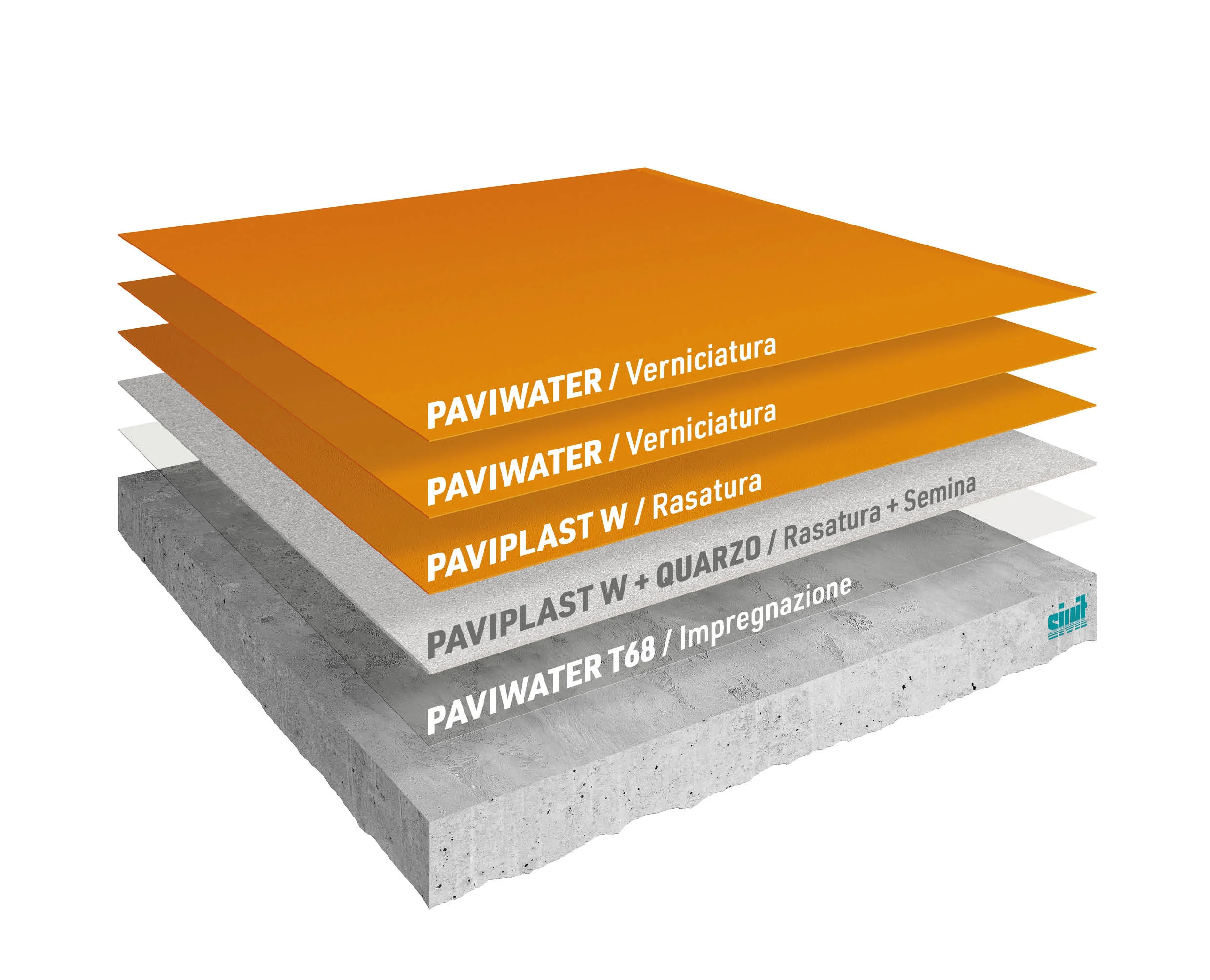

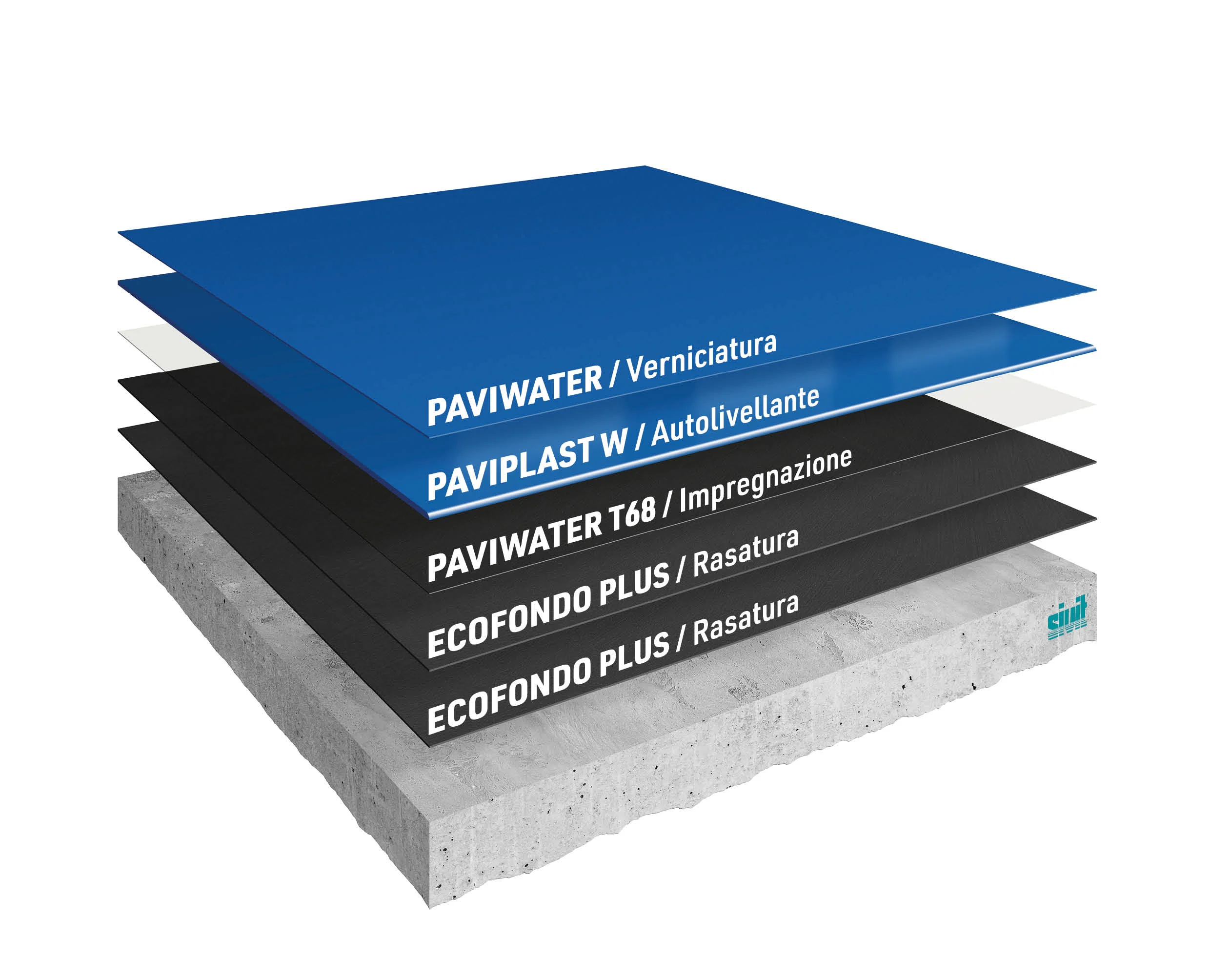

Valutare il tipo di preparazione meccanica più conveniente (levigatura, pallinatura o fresatura). quindi applicare due mani di ECOFONDO. La prima mano a rullo diluita 15% con consumo di 0,20-0,25 kg/m2. La seconda caricata con il 10% in peso di QUARZO B1 con consumo totale di circa 0,50 Kg/m2.

Fondi in piastrelle vanno pallinati energicamente. Eventuali piastrelle non ancorate vanno rimosse, ripristinando con PAVIRAPID. Come primer utilizzare ECOFONDO PLUS FIBRATO o ECOFONDO

Applicazione

PAVIPLAST W GIA' IN TINTA.

Al momento dell’applicazione unire i due componenti in un unico recipiente. Miscelare con cura per 2 minuti, utilizzando adeguata attrezzatura (trapano con elica) e avendo cura di pulire con spatola le pareti dei contenitori al fine di miscelare tutto il prodotto.

PAVIPLAST W NP + COLORPASTA W.

Mescolare bene la pasta colorante per omogeneizzare eventuali sedementi.

Al momento dell'applicazione unire 5% in peso di COLORPASTA W al componente A e miscelare con cura. Aggiungere poi il componente B e miscelare per 2 minuti, utilizzando adeguata attrezzatura (trapano con elica) e avendo cura di pulire con spatola le pareti dei contenitori al fine di miscelare tutto il prodotto.

Utilizzo come Autolivellante

Dopo avere miscelato stendere rapidamente il prodotto con spatola o racla dentata. Per uniformare la superficie e favorire la disareazione passare il rullo frangibolle con movimenti lenti e regolari.

Il consumo per 2,5 mm di spessore è di 4,00 kg/m2 di (A+B)

Il rivestimento finale presenta aspetto opaco finemente antisdrucciolevole. Per ottenere una finitura più lucida applicare una ripresa di finitura all’acqua trasparente o colorata.

Utilizzo come Rasante

Dopo avere miscelato stendere rapidamente il prodotto (A+B) con spatola con un consumo di circa 0,80 kg/m2.

Utilizzo come Rasante in Ciclo Multistrato

Dopo avere miscelato i componenti (A+B) caricare con 20% di QUARZO B1 e stendere rapidamente con spatola con un consumo compreso tra 0,4-0,8 kg/m2.

Avvertenze

Diversi lotti di produzione del medesimo colore possono presentare piccole differenze: ove possibile utilizzare materiale proveniente da un unico lotto di produzione.

Alcuni colori a base di pigmenti organici (rossi, blu, verdi, gialli intensi, ...) tendono a cedere colore nel caso in cui siano sottoposti ad abrasione (a secco o a umido): in questi casi si consiglia di proteggere il colore con una ripresa di finitura trasparente.

Prodotto ad uso professionale, l’acquirente si impegna a seguire tassativamente le avvertenze sopra riportate nell’applicazione del prodotto acquistato e le indicazioni della scheda di sicurezza.

Specifiche tecniche

| DATI PRODOTTO | |

|---|---|

| Colore | A richiesta secondo cartelle colore. |

| Consumo | a rasare: 0,80 kg/m2 di (A+B) circa come autilivellante: 4,00 kg/m2 di (A+B) (per 2,5 mm di spessore) |

| Peso specifico (a 25°C) | miscela (A+B): 1,90-2,20 g/ml |

| Viscosità (a 25°C) | miscela (A+B): 60.000-80.000 mPa•s (spindle 2, rpm 5) |

| Residuo secco | 88% in peso |

| Punto di infiammabilità | Non applicabile |

| Solvente per la pulizia attrezzi | Acqua |

| Magazzinaggio | 12 mesi, conservare in luogo asciutto ad una temperatura compresa tra i 15°C ed i 35°C L'applicazione e la reticolazione del prodotto deve avvenire a temperatura maggiore di 15°C per non compromettere lo sviluppo delle proprietà meccaniche ed estetiche finali. |

| DATI TECNICI PRESTAZIONALI | |

|---|---|

| Aspetto | Opaco |

| Resistenza all’abrasione norma UNI 8298-9 | < 100 mg (TABER Mola CS-17-1000 giri – 1000 g di peso) |

| Resistenza a compressione (UNI 4279) | 35 N/mm2, con 7 giorni di indurimento, a 25°C e 50% U.R. |

| Durezza (ASTM D 2240) | >80 Shore D |

| Reazione al fuoco (UNI EN 13501-1:2007) | Bfl-s1 |