ECOFER® RASATURA A+B+C

Malta epossidica rinforzata con granacciaio trattato

Malta epossidica rinforzata a base acqua per rasatura di pavimentazioni soggette a forte usura superficiale.

Tipologia: Formulati Epossidici a Base Acquosa

Descrizione

Prodotto a 3 componenti:

A - resina amminica in veicolo acquosa

B - resina epossidica

C - preconfezionato a base di granulato metallico post-trattato ed additivi inorganici

La malta consente di ottenere rivestimenti con alte resistenze meccaniche, indurimento in presenza di umidità ed ottime caratteristiche di permeabilità.

Utilizzi

Pavimentazioni industriali con forte usura superficiale.

Pavimenti di magazzini e locali commerciali soggetti ad alto transito.

Supporto

Il sottofondo deve possedere una resistenza minima alla compressione di 25 N/mm2 e a trazione di 1,5 N/mm2.

Preparazione del supporto

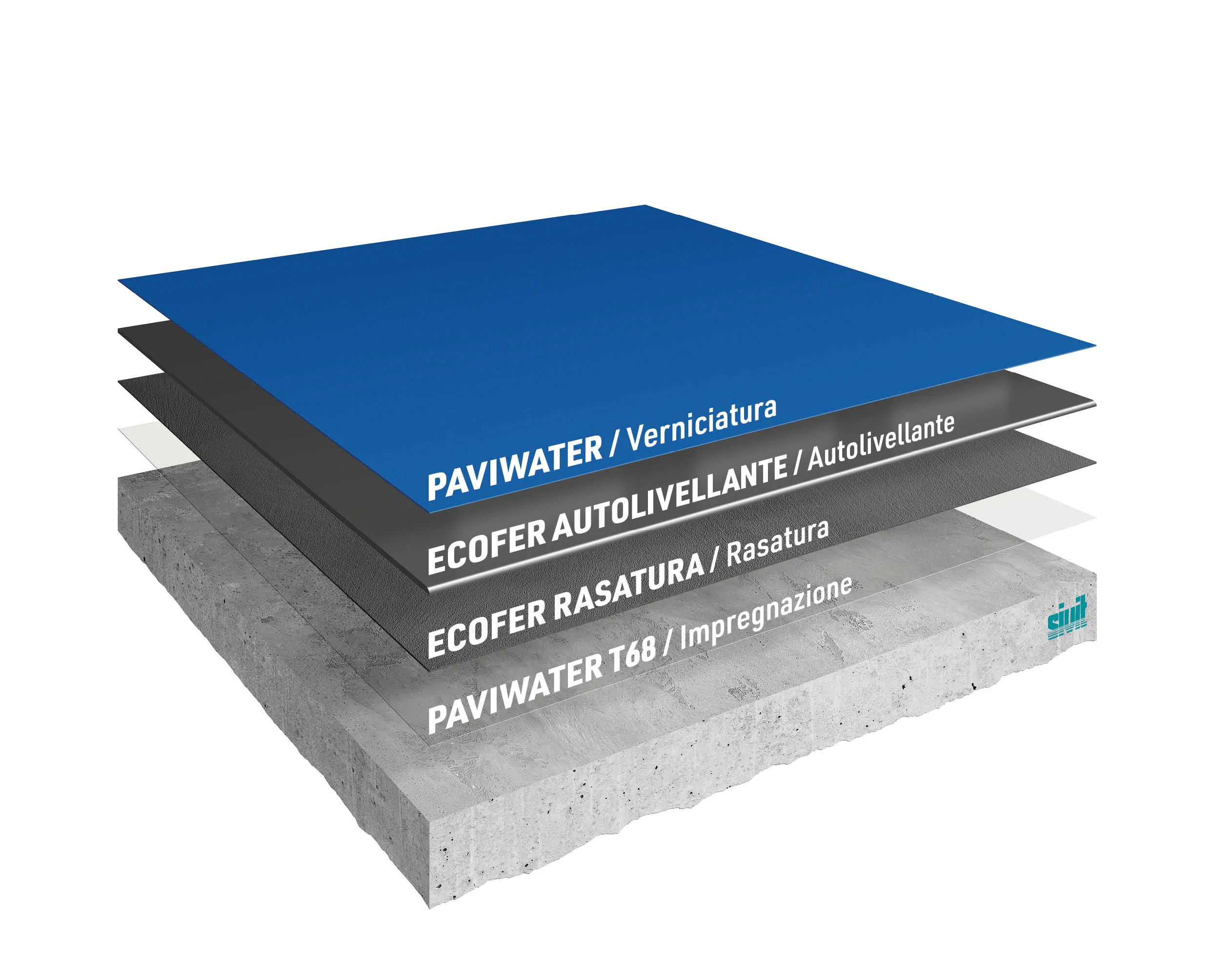

Fondi in cls. dovranno essere solidi, livellati, assorbenti, non inquinati da oli, polvere od altre sostanze. Verificare tipo di preparazione meccanica più conveniente (abrasivazione, pallinatura o fresatura) e quindi applicare una ripresa di PAVIWATER T68.

Superfici oleose vanno fresate in profondità e trattate rasando con FLUIDEPOX (1 kg/m2) caricato con QUARZO B0; sul prodotto appena applicato cospargere QUARZO B2 a rifiuto(2 kg/m2). La stessa soluzione può essere adottata per spianare eventuali irregolarità del sottofondo, come i solchi lasciati dalla fresatura, e per consolidare fondi che non danno garanzia di solidità.

N.B.: con questo trattamento viene ridotta la traspirabilità del rivestimento.

Fondi in piastrelle vanno pallinati, quindi trattati con una ripresa di FONDO PER PIASTRELLE. Eventuali piastrelle non ancorate vanno rimosse, ripristinando con ECOPAVIPLAST opportunamente caricato con QUARZO B3 (1 a 1 in peso).

Superfici irregolari possono essere spianate rasando con ECOPAVIPLAST o MALTA C.

Applicazione

Preparare a parte la miscela dei 2 componenti liquidi (A+B), versando il contenuto della parte B nel contenitore della parte A, e quindi miscelare con trapano per circa 2 minuti.

Aggiungere alla miscela (A+B) le polveri (parte C) ed omogeneizzare con trapano miscelatore per circa 1 minuto. Per disperdere in modo ottimale il prodotto occorre versare poco per volta le polveri, continuando a rimescolare con il trapano.

Stendere il prodotto rapidamente.

Distribuire con racla liscia o con cazzuola americana, per un consumo di 0,5-1,0 kg/m2 per ogni ripresa.

Finire con PAVIWATER, per un consumo di 0,15 kg/m2.

Se ECOFER RASATURA deve essere rivestito con vernici non traspiranti, aspettare 24 ore, per consentire l’evaporazione dell’acqua.

Avvertenze

Prodotto ad uso professionale, l’acquirente si impegna a seguire tassativamente le avvertenze sopra riportate nell’applicazione del prodotto acquistato e le indicazioni della scheda di sicurezza.

Specifiche tecniche

| DATI PRODOTTO | |

|---|---|

| Colore | Grigio cemento o a richiesta per quantitativi |

| Peso specifico (a 25°C) | miscela (A+B): 2,5 +/- 0,1 g/ml (rif. RAL 6021) |

| Viscosità (a 25°C) | miscela (A+B): 4.000 +/- 800 mPascal (spindle 3, rpm 5, rif. RAL 6021) |

| Residuo secco | 84,3% in peso (rif. RAL 6021) |

| Punto di infiammabilità | Non applicabile |

| Solvente per la pulizia attrezzi | Acqua |

| Magazzinaggio | Conservare in luogo asciutto e protetto, ad una temperatura compresa tra i 5°C ed i 35°C: 6 mesi per la parte C, 12 mesi per i componenti A e B |

| DATI APPLICAZIONE E TEMPI | |

|---|---|

| Rapporto di miscela | A=45, B=30, C=100 |

| Pot-life (50% U.R.) | a 5°C > 25min a 25°C 15 min a 30°C > 10 min |

| Secco al tatto (50% U.R.) | a 5°C 5,5-7,5 ore a 25°C 2-3 ore a 30°C 1-2 ore |

| Pedonabile (50% U.R.) | a 25°C 8 ore |

| Condizioni ambientali d’uso | Temperature comprese tra i +5°C e i +30°C |

| DATI TECNICI PRESTAZIONALI | |

|---|---|

| Resistenza a compressione (UNI 4279) | 55 N/mm2 (indurimento 7 gg a 25°C e 50% U.R.) |

| Resistenza a flessione (UNI 7219) | 25 N/mm2 (indurimento 7 gg a 25°C e 50% U.R.) |