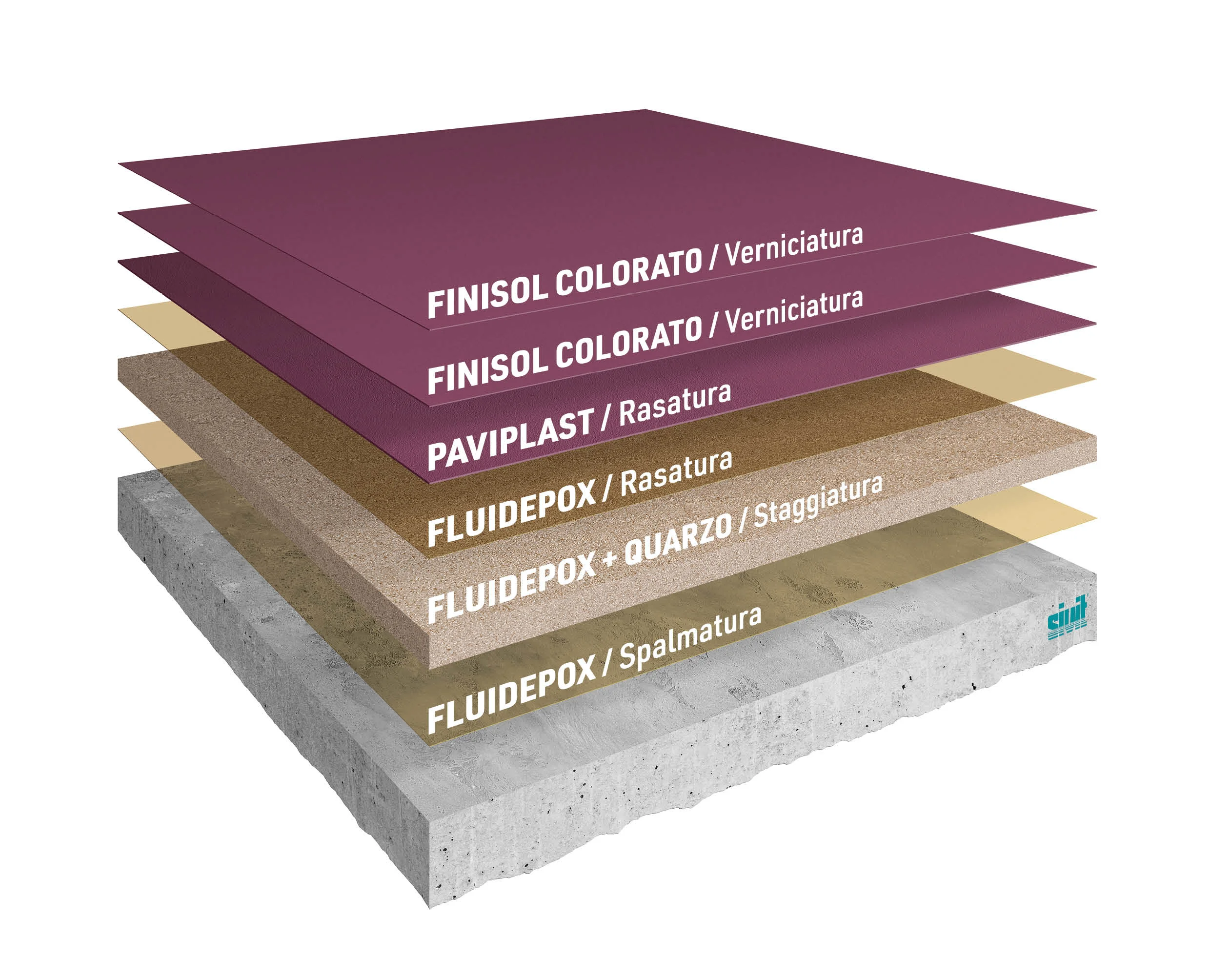

Rivestimento a massetto con finitura poliuretanica

Ciclo in massetto colorato per locali alimentari, dello spessore di circa 6 mm, applicabile sia su supporti cementizi che in piastrelle.

Il ciclo é a base di malta epossidica e formulati ad alto contenuto di solidi.

La finitura poliuretanica a solvente conferisce al pavimento le proprietà di resistenza chimica richieste dai locali ad uso alimentare.

Preparazione del supporto

Fondi in cls dovranno essere solidi, asciutti, livellati, assorbenti, non inquinati da oli, detergenti, polveri od altre sostanze. Per i massetti di nuova realizzazione si dovrà rispettare il normale tempo di stagionatura. Valutare il tipo di preparazione meccanica più conveniente: pallinatura o fresatura. Su pavimenti in cemento vecchi, ammalorati e contaminati si dovrà procedere all’asportazione dello strato superficiale, fino ad eliminazione completa delle parti inconsistenti ed in fase di distacco, in modo da lasciare aperte le porosità ed arrivare ad una superficie compatta.

Applicazione

- Applicare a rullo una ripresa di FLUIDEPOX per un consumo di 0,50-0,80 kg/m2 . Nel medesimo giorno, distribuire, fresco su fresco, la malta costituita da FLUIDEPOX e Quarzo (in curva granulometrica Mix1-Mix3) preparata in apposita impastatrice (con un rapporto di 1 a 15). Utilizzare racla e rigone distribuendo la malta sulla pavimentazione per un consumo di circa 10,4 kg/m2 (0,65 kg/m2 di FLUIDEPOX e 9,75 kg/m2 di Quarzo). Compattare con frattazzatrice a pale rotanti.

- Rasare e saturare le porosità con 1,0 kg/m2 di FLUIDEPOX. Per l’applicazione si utilizza la cazzuola americana liscia.

- Rasare la superficie con PAVIPLAST, caricato 1 a 0,8 con Quarzo B0, per un consumo di PAVIPLAST di circa 0,4 kg/m2 . Per l’applicazione si utilizza la cazzuola americana liscia.

- Applicare a rullo una ripresa di finitura poliuretanica FINISOL COLORATO LUCIDO per un consumo di circa 0,13 kg/m2.

- Applicare a rullo una seconda ripresa di FINISOL COLORATO LUCIDO per un consumo di circa 0,13 kg/m2.

- Procedere al taglio del rivestimento in corrispondenza dei giunti del cls e sigillare con elastomero poliuretanico SIGILFLEX.

Lo spessore risultante del rivestimento è di circa 6 mm

Sgusci

Prima della posa del rivestimento, è possibile costruire lo sguscio per il raccordo fra parete e pavimento. Per questa operazione utilizzare la malta PAVIRAPID SGUSCI lasciando un raggio di curvatura di circa 4 cm. Lo sguscio viene quindi coperto rasando con PAVIPLAST e FINISOL COLORATO LUCIDO.