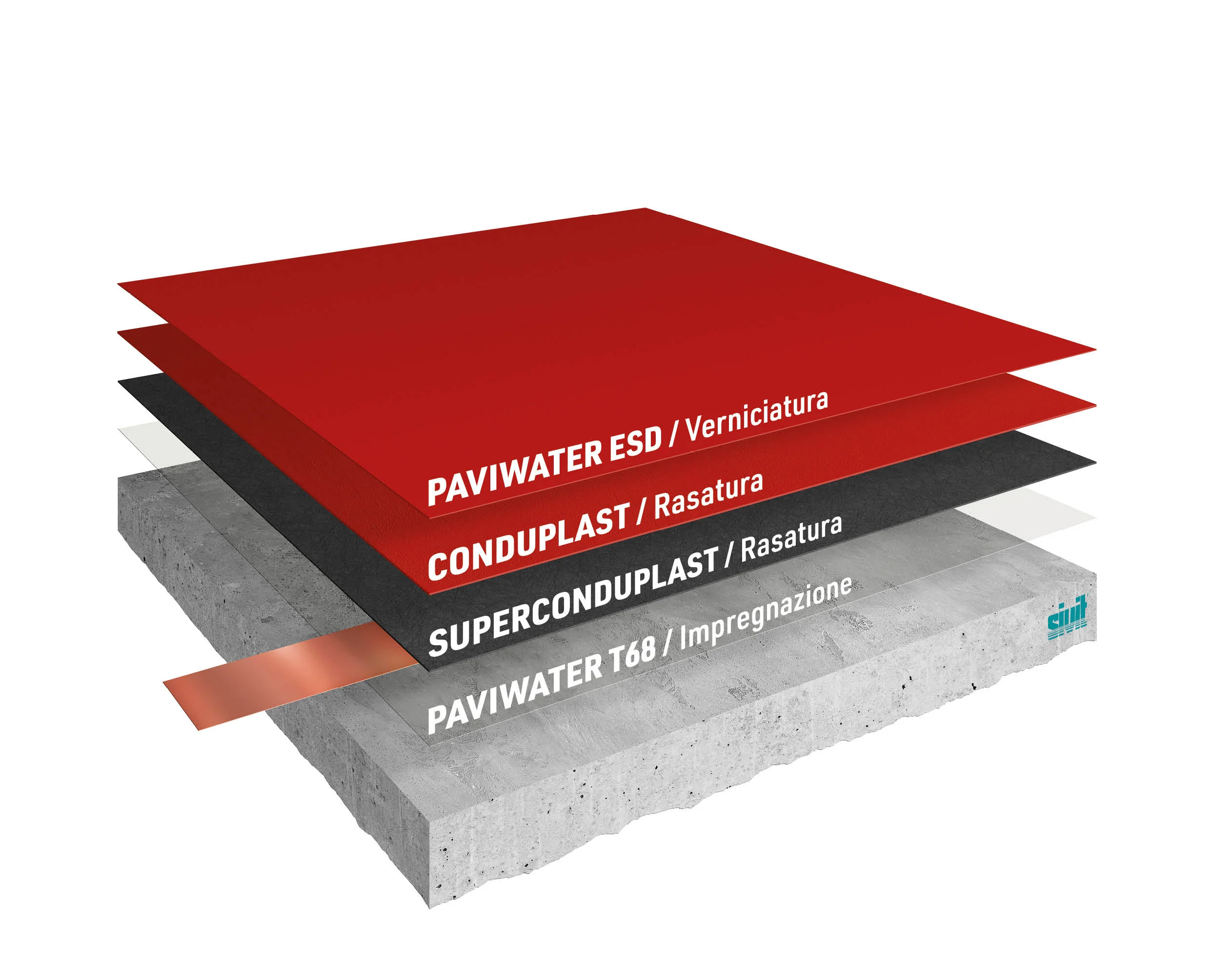

Ciclo in grado di dissipare le cariche elettrostatiche ed evitare scariche dannose (ESD)

Ciclo di rasatura colorata, per supporti cementizi esenti da umidità di risalita in grado di dissipare le cariche elettrostatiche.

Il ciclo é a base di resine epossidiche, con formulati ad alto contenuto di solidi, per uno spessore di circa 1 mm.

I prodotti sono trattati con l'aggiunta di sostanze altamente conduttive, in modo da ottenere pavimentazioni antistatiche, tali cioè da avere caratteristiche di conducibilità elettrica in grado di evitare l’accumulo di cariche elettrostatiche.

Tipici campi di impiego dei rivestimenti antistatici sono: l'industria chimica, elettronica, meccanica (in particolare in presenza di carrelli AGV), le sale operatorie e laddove vi sia il rischio di presenza di atmosfere infiammabili o esplosive.

Preparazione del supporto

Fondi in cls dovranno essere solidi, asciutti, livellati, assorbenti, non inquinati da oli, detergenti, polveri od altre sostanze. Per i massetti di nuova realizzazione si dovrà rispettare il normale tempo di stagionatura.

Valutare il tipo di preparazione meccanica più conveniente: levigatura o pallinatura.

Essendo un ciclo non traspirante si dovrà verificare l’esistenza di una barriera vapore e comunque non si dovrà avere risalita di umidità (in caso contrario optare per il ciclo autolivellante AUT07). Si dovrà inoltre prevedere una messa a terra del cls, in modo da garantire una resistenza compresa fra 10.000 ed 100.000 Ohm.

Applicazione

- Al fine di saturare le porosità del pavimento, applicare a rullo una ripresa di PAVIWATER T68, diluito 1 a 3 con acqua, per un consumo di prodotto di circa 0,05 kg/m2.

- Predisporre dei punti di messa a terra tramite l’applicazione di bandelle di rame in prossimità delle scatole elettriche. Rasare a spatola liscia con SUPERCONDUPLAST, caricato del 30% con Quarzo B0 (consumo di SUPERCONDUPLAST 0,40 kg/m2 ).

- Se necessario, tamponare i giunti di dilatazione con SUPERCONDUPLAST, caricato 1 a 3 con Quarzo B1 (il consumo di prodotto è trascurabile). Rasare a spatola liscia con CONDUPLAST, caricato del 30% con Quarzo B0, per un consumo di CONDUPLAST di 0,30 kg/m2.

- Applicare a rullo PAVIWATER ESD, diluito con il 10% di acqua, per un consumo di circa 0,13 kg/m2.

- Procedere al taglio del rivestimento in corrispondenza dei giunti del cls e sigillare con elastomero poliuretanico SIGILFLEX.

Lo spessore risultante del rivestimento è di circa 1,0 mm.