Guida alla certificazione LEED®: il ruolo chiave delle pavimentazioni in resina

20 Maggio 2025

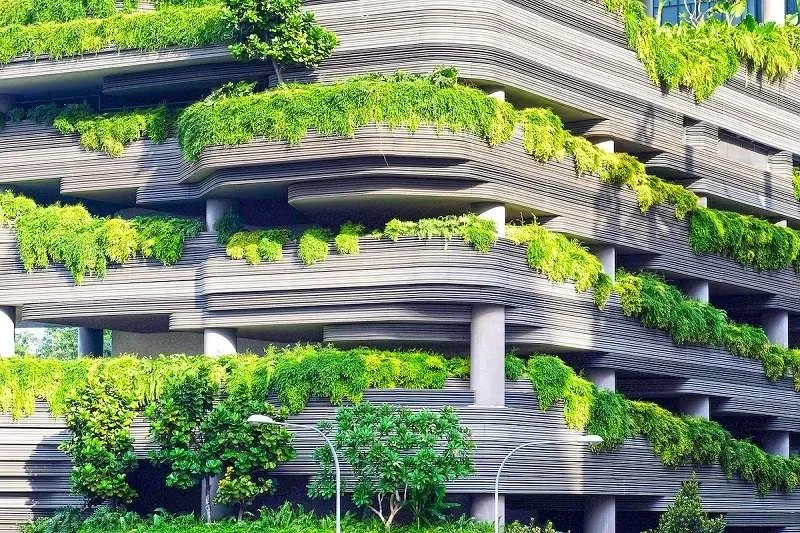

Sono finiti i tempi dell’edilizia incontrollata. Negli ultimi decenni, complici i problemi ambientali che affliggono il pianeta, si è infatti affermato un nuovo modo di costruire: il green building, il cui obiettivo è ridurre o eliminare l’impatto dell’uomo sull’ambiente circostante.

Anche il mondo delle resine, utilizzate in ambito industriale o residenziale, si è evoluto in questo senso, privilegiando formulazioni all’acqua, eliminando il più possibile i solventi e sviluppando nuovi prodotti a base vegetale o realizzati con materiali riciclati.

Nell’articolo vedremo cosa significa esattamente green building, perché è nato, come si collocano le resine nel trend della bioedilizia e qual è il rapporto tra resine e certificazione LEED, che attesta l’impronta ecologica di edifici residenziali e commerciali.

Negli ultimi decenni sono aumentati notevolmente i problemi ambientali causati da inquinamento, scarsità di acqua, cambiamenti climatici, produzione di gas serra. Da questa situazione è nata una maggiore consapevolezza delle responsabilità dell’uomo nei confronti dell’ambiente, e una maggiore sensibilità verso i danni provocati durante i processi di costruzione.

Dall’unione di questi elementi è nato il green building, un modo nuovo e diverso di progettare edifici, quartieri e città.

Il trend è in costante crescita: al momento sono stati costruiti più di tre miliardi di metri quadrati di edifici “green”, e le ricerche mostrano che i numeri di questo mercato raddoppiano ogni tre anni.

Ma cosa si intende esattamente quando parliamo di green building?

Secondo la definizione del World Green Building Council, con il termine “green building” si intende la pratica di progettare e costruire edifici in modo da eliminare o ridurre impatti negativi sull’ambiente e sul clima.

L’obiettivo è migliorare la qualità della vita e difendere le risorse naturali.

Ecco alcune caratteristiche che rendono green un edificio:

Un edificio green, quindi, contribuisce a mantenere inalterato l’ambiente e le risorse naturali che lo circondano, offrendo allo stesso tempo ai suoi abitanti vantaggi tangibili in termini di salute e stile di vita.

Molti si staranno facendo questa domanda: “cos’hanno a che fare le resine con il green building? Anche loro possono essere ecologiche?”.

Si, anche le resine possono essere green. Ne abbiamo parlato negli articoli “Resine ecologiche per pavimenti. Esistono davvero?” e “Resine a base d’acqua: rispetto dell’ambiente, rispetto dell’uomo”; ripercorriamo qui brevemente le loro caratteristiche eco sostenibili.

Mentre un tempo erano reperibili in commercio soprattutto resine a base di solventi, oggi sono utilizzate soprattutto le resine all’acqua, più rispettose della salute dell’uomo e dell’ambiente.

Numerose formulazioni, ad esempio, sono in regola con le soglie fissate per limitare la presenza di VOC, sostanze chimiche volatili che, inalate, possono causare irritazione delle vie respiratorie, asma, allergie, emicranie ecc.

I pavimenti in resina possono anche migliorare la qualità dell’aria: essendo impermeabili, non producono umidità e scoraggiano il ristagno di batteri.

La manutenzione è facile e veloce: per pulire un pavimento in resina, infatti, bastano acqua e uno straccio. Questo significa che è possibile evitare l’uso di detersivi, detergenti e solventi aggressivi, a tutto vantaggio dell’uomo e dell’ambiente.

Esistono poi le resine epossidiche solide, formulate senza acqua né solventi: durante la posa e una volta asciutte, quindi, non emettono gas nocivi né odori fastidiosi.

I pavimenti in resina consentono anche di risparmiare energia elettrica, perché la loro superficie è in grado di aumentare la luminosità ambientale del 300%.

Su substrati di cemento o altri materiali, lo strato di resina funziona da “sigillante”, perché impedisce a eventuali sostanze nocive rilasciate durante il normale processo di invecchiamento dell’edificio di contaminare l’ambiente.

I pavimenti in resina sono alleati green anche in caso di ristrutturazione: nella maggior parte dei casi, infatti, non è necessario rimuovere il vecchio pavimento, operazione che crea rifiuti spesso difficili da smaltire. Dopo un’adeguata preparazione, infatti, la resina può essere posata senza problemi sulla superficie esistente.

Le certificazioni che attestano la responsabilità ambientale edifici e progetti sono numerose, ma la più famosa e diffusa nel mondo è la LEED, acronimo di Leadership in Energy & Environmental Design.

Si tratta di un accreditamento che certifica l’impronta green di edifici residenziali o commerciali a partire dalla progettazione fino ad arrivare al lavoro finito. L’obiettivo è incentivare la sostenibilità, ponendo massima attenzione a temi come l’impatto sull’ambiente, il risparmio energetico e idrico, l’emissione di gas serra, la vivibilità degli interni, i materiali scelti.

E, quando si tratta di scegliere materiali green per le pavimentazioni, in numerosi progetti fanno la loro comparsa proprio le resine, studiate per essere il più innovative ed eco friendly possibile.

Ad esempio, molti pavimenti in resina effetto marmo sono realizzati unendo alla resina epossidica materiali riciclati come il vetro, che aggiungono brillantezza e ampliano la gamma di colori disponibili. Allo stesso tempo, riducono notevolmente la produzione di rifiuti, i costi di smaltimento e l’impiego di risorse energetiche necessarie alla loro eliminazione.

In un’ottica di sostenibilità, un altro vantaggio dei pavimenti in resina è la loro durabilità: il loro ciclo di vita, infatti, supera spesso quello dell’edificio stesso in cui sono posati! Inoltre, per mantenere l’aspetto originario dei pavimenti in resina basta spesso solo il lavaggio con acqua, mentre la manutenzione straordinaria, che comprende la stesura di apposite cere, può essere fatta a distanza di molti anni.

Lo sviluppo di bioresine derivate da sostanze naturali sta dando un’ulteriore spinta alla presenza di questo materiale all’interno di progetti di green building.

La certificazione LEED, infatti, incoraggia l’uso di materiali a base di elementi riciclati o biologici.

Ecco che, ad esempio, si stanno sviluppando resine derivate da grano o semi di soia, disponibili in grande abbondanza soprattutto nelle regioni americane.

Numerose imprese edili impegnate in progetti di green building che puntano alla certificazione LEED utilizzano resina poliestere insatura prodotta da alcoli a base di mais e olio di soia: si tratta di una delle prime bioresine lanciate sul mercato.

Molti produttori, nelle loro resine epossidiche, usano anche sottoprodotti del biodiesel come oli di pino epossidato e glicerina, inserendo così nelle formulazioni una percentuale di materiali a base vegetale del 30% – 70%.

Al momento l’utilizzo diffuso di bioresine è frenato dai costi di produzione, che si mantengono elevati. Sono però sempre più numerosi i produttori che stanno sperimentando nuove formulazioni, e sono sempre più numerosi gli utilizzatori finali interessati ad alternative 100% green nel campo delle resine.

Il sodalizio bioresine, resine e green building è solo all’inizio!

Per maggiori informazioni sulla nostra gamma di resine industriali e per richiedere un preventivo personalizzato è possibile contattare Sivit al numero + 39 011 2730033 o alla mail commerciale@sivit.it

Negli ultimi anni è aumentata la richiesta di soluzioni costruttive sempre più rispettose dell’ambiente e della salute dell’uomo.

In questo panorama, anche i produttori di resine industriali hanno cominciato a proporre formulazioni sempre più eco friendly e a ricercare sempre più spesso ingredienti derivati da elementi naturali.

In questo articolo vedremo tre tipi di resine eco friendly utilizzate per la realizzazione di pavimenti industriali: le resine epossidiche a base acquosa, le resine poliuretaniche all’acqua e le resine epossidiche solide.

Fino a qualche anno fa, il mercato era dominato soprattutto da resine epossidiche addizionate a solventi.

Questo perché:

Proprio i solventi, però, rendevano le resine altamente infiammabili, con notevoli rischi per gli operatori e le strutture stesse in cui il materiale veniva posato.

Il difetto più importante, però, era l’alta concentrazione di VOC (Volatile Organic Compounds), cioè composti organici volatili. Si tratta di composti chimici di vario tipo, che hanno in comune l’evaporazione a temperatura ambiente, e che vengono quindi inalati facilmente.

Le conseguenze dei VOC sulla salute delle persone dipende dal tempo di esposizione e dallo stato di manutenzione dei materiali che li contengono ma, in generale, gli effetti più comuni sono irritazione delle vie respiratorie, emicranie, disturbi della vista, nausea, stanchezza cronica.

L’alta concentrazione di VOC nelle vecchie resine epossidiche ha determinato, nel tempo, la loro sempre più frequente sostituzione con le resine epossidiche a base acquosa.

Si tratta di formulati privi di solventi pericolosi, che possono quindi essere utilizzati senza problemi nelle aree industriali in cui lavorano gli operatori. Quando vengono posati non emettono odori intensi e non contaminano cibo e bevande. Un vantaggio importante soprattutto per le aziende che operano nel settore alimentare.

Proprio l’attenzione all’ambiente e alla salute dell’uomo che ha determinato lo sviluppo delle resine epossidiche all’acqua ha portato alla ricerca di soluzioni eco friendly anche per le resine poliuretaniche.

Le resine poliuretaniche all’acqua non contengono VOC né isocianati, sostanze chimiche irritanti che possono causare problemi alle vie respiratorie, asma, allergie e cefalee.

Come le resine epossidiche all’acqua, durante la posa non emettono quasi odori e non sono infiammabili.

Inoltre, la formulazione con acqua rende la posa adatta anche su substrati che potrebbero venire danneggiati dai solventi.

Oggi sono numerose le aziende che offrono resine poliuretaniche a base acquosa, che trovano applicazione in numerosi ambienti.

In particolare, questo tipo di resina è spesso posata all’interno di aziende che lavorano latte, formaggi e latticini grazie alla sua alta resistenza all’acido lattico. La mancanza di solventi, poi, garantisce che non vi siano cessioni di sostanze nocive.

Lo spessore finale delle resine poliuretaniche all’acqua va di solito dai 6 ai 9 millimetri, il che li rende la scelta ideale anche in zone sottoposte a continuo traffico pesante. Proprio l’alto spessore permette anche la pulitura con il vapore, caratteristica importante per ambienti che devono essere frequentemente sterilizzati (es: industrie chimiche o ospedali).

Tra gli altri vantaggi offerti dalle resine poliuretaniche all’acqua:

Sivit ha sviluppato una gamma di finiture poliuretaniche all’acqua in grado di combinare alta efficienza e rispetto dell’ambiente: per conoscere le loro applicazioni, visita la sezione Finiture poliuretaniche a base acquosa.

Tra le resine epossidiche rispettose dell’ambiente ci sono le resine epossidiche solide, che non contengono né acqua né solventi di alcun tipo. Non essendoci quindi evaporazione, lo strato che si produce è più spesso rispetto a quello delle resine a base di acqua o solvente; di solito è di circa 10 millimetri.

Inoltre, non ci sono variazioni di spessore tra il momento della posa, quando la resina è liquida, e quando il pavimento è pronto per essere calpestato. Questa caratteristica permette di raggiungere il risultato finale con meno passate di prodotto.

Come le resine esaminate in precedenza, le resine epossidiche solide sono prive di VOC e non emettono odori fastidiosi: questo le rende adatte all’applicazione in ambienti di trasformazione alimentare, clean room, aziende farmaceutiche, luoghi pubblici e scuole.

Oltre ad essere rispettose dell’ambiente, le resine epossidiche solide sono molto resistenti alle sostanze chimiche e alla corrosione e hanno una vita decisamente lunga.

Anche dal punto di vista della resa estetica, questo tipo di resina permette di ottenere un aspetto lucido e vetroso, che resiste inalterato nel tempo.

Le resine a base di acqua e le resine epossidiche solide sono il primo passo verso una concezione più ecosostenibile di costruire, ma sono già oggetto di studio numerose alternative in grado di offrire gli stessi risultati delle resine tradizionali con un impatto sull’ambiente decisamente minore.

Al momento, le alternative oggetto di studio sono due:

Resine ecologiche

Questo tipo di resina è prodotto in modo da consumare il minimo di risorse energetiche, non crea emissioni nocive per l’uomo e per l’ambiente e può essere smaltito in modo sicuro.

Alcune resine ecologiche possono essere riciclate o ridotte a materiale biologico sicuro.

Resistenza ad abrasione e traffico, elasticità, idrorepellenza e longevità rimangono immutate rispetto alle resine tradizionali.

Bio resine

Si tratta di resine derivate soprattutto da oli naturali e piante come patate, soia, girasole, grano o risorse rinnovabili come la fecola di patate.

Il loro sviluppo permetterà non solo di evitare i danni alla salute causati da prodotti che ancora contengono fenoli, formaldeide e altri derivati del petrolio, ma anche di ridurre la produzione di anidride carbonica e gas serra.

Hai un progetto di costruzione o ristrutturazione che vorresti realizzare? Contatta Sivit al numero + 39 011 2730033 o alla mail commerciale@sivit.it: siamo a tua disposizione per ogni informazione!