FINIWATER® SATINATO A+B

Vernice poliuretanica trasparente satinata alifatica a base acquosa

Vernice poliuretanica bicomponente a base acqua. Idonea per la finitura di pavimenti e rivestimenti in resina o calcestruzzo.

Buone resistenza chimiche e meccaniche.

Aspetto satinato.

Tipologia: Finiture Poliuretaniche a Base Aquosa

Descrizione

Prodotto bicomponente a base di dispersione poliuretanica reticolata con un poliisocianato alifatico idrofilo.

Il film che si ottiene dopo la fase di coalescenza e di reticolazione presenta le seguenti caratteristiche:

- elevate proprietà di ancoraggio su vari supporti

- ottime proprietà meccaniche

- buona resistenza all’abrasione

- buona resistenza ai solventi

- ottima resistenza agli agenti atmosferici

- buona resistenza nei confronti dell’alcool etilico

- aspetto satinato

Utilizzi

Finitura trasparente di rivestimenti in resina.

Finitura trasparente di rivestimenti decorativi e pitture.

Verniciatura di pavimenti in calcestruzzo.

Preparazione al supporto

Ogni supporto deve essere pulito, sgrassato e privo di vecchi rivestimenti in fase di distacco.

In caso di finitura di rivestimenti in resina, è necessario verificare il tempo di ricopertura del prodotto precedentemente applicato.

Abrasivare superficialmente per favorire l’adesione.

Si consiglia di utilizzare carte abrasive chiare con grana 150 o più fine. Dopo l’abrasione rimuovere completamente la polvere dalla superficie.

Superfici tendenti a sfarinare o molto assorbenti devono essere trattate con una ripresa di PAVIWATER T68 o di PAVIWATER TES, entrambi diluiti 1:3 con acqua.

Applicazione

Al momento dell’applicazione unire il componente B al componente A miscelando con cura con agitatore meccanico.

Applicare la miscela a rullo con un consumo di 0,100 kg/m2. Per l'applicazione si consiglia l’impiego di idonei rulli a pelo medio.

Per ottenere una superficie ruvida e antisdrucciolevole aggiungere alla miscela 3% in peso di SFERETTE DI VETRO FINI (vedere tabella).

Evitare film troppo spessi per consentire il corretto sviluppo delle caratteristiche chimico-fisiche nominali del film.

Se necessario è possibile diluire la miscela con acqua fino ad un massimo del 10%.

Attenzione: in virtù della velocità di essiccazione di questa tipologia di prodotti si presti particolare attenzione al momento della stesura, al fine di evitare inestetismi come rullate, sormonti e differenze di gloss. In linea generale si proceda a distribuire la vernice sul supporto in modo omogeneo nella giusta quantità; nel congiungersi con l'area appena verniciata si abbia cura di riprendere la verniciatura a qualche centimetro di distanza in modo da scaricare l'eccesso di prodotto e raccordarsi poi con la precedente area sfumando e dosando la quantità applicata con attenzione. Non attendere troppo per le sovrapposizioni, verniciare sempre “fresco su fresco”.

Prestare attenzione a non lasciare zone non verniciate, nel dubbio si consiglia l’applicazione di due mani di prodotto.

Nella realizzazione di grandi superfici è necessario il movimento coordinato di diversi applicatori.

Note: qualora si debba travasare il componente A dalla sua confezione originale, si mescoli con cura al fine di omogeneizzare gli agenti opacanti eventualmente sedimentati ed ottenere così il valore di gloss nominale.

Specifiche tecniche

| DATI PRODOTTO | |

|---|---|

| Colore | Trasparente |

| Consumo (a rullo) | 0,100-0,125 kg/m2 |

| Peso specifico (a 25°C) | miscela (A+B): 1,00 +/- 0,05 g/ml |

| Viscosità (a 25°C) | miscela (A+B): 300 +/- 30 mPa•s (spindle 2, rpm 50) miscela (A+B), diluita al 10%: 120 +/- 30 mPa•s (spindle 1, rpm 50) |

| Residuo secco (A+B) | 40-42% in peso |

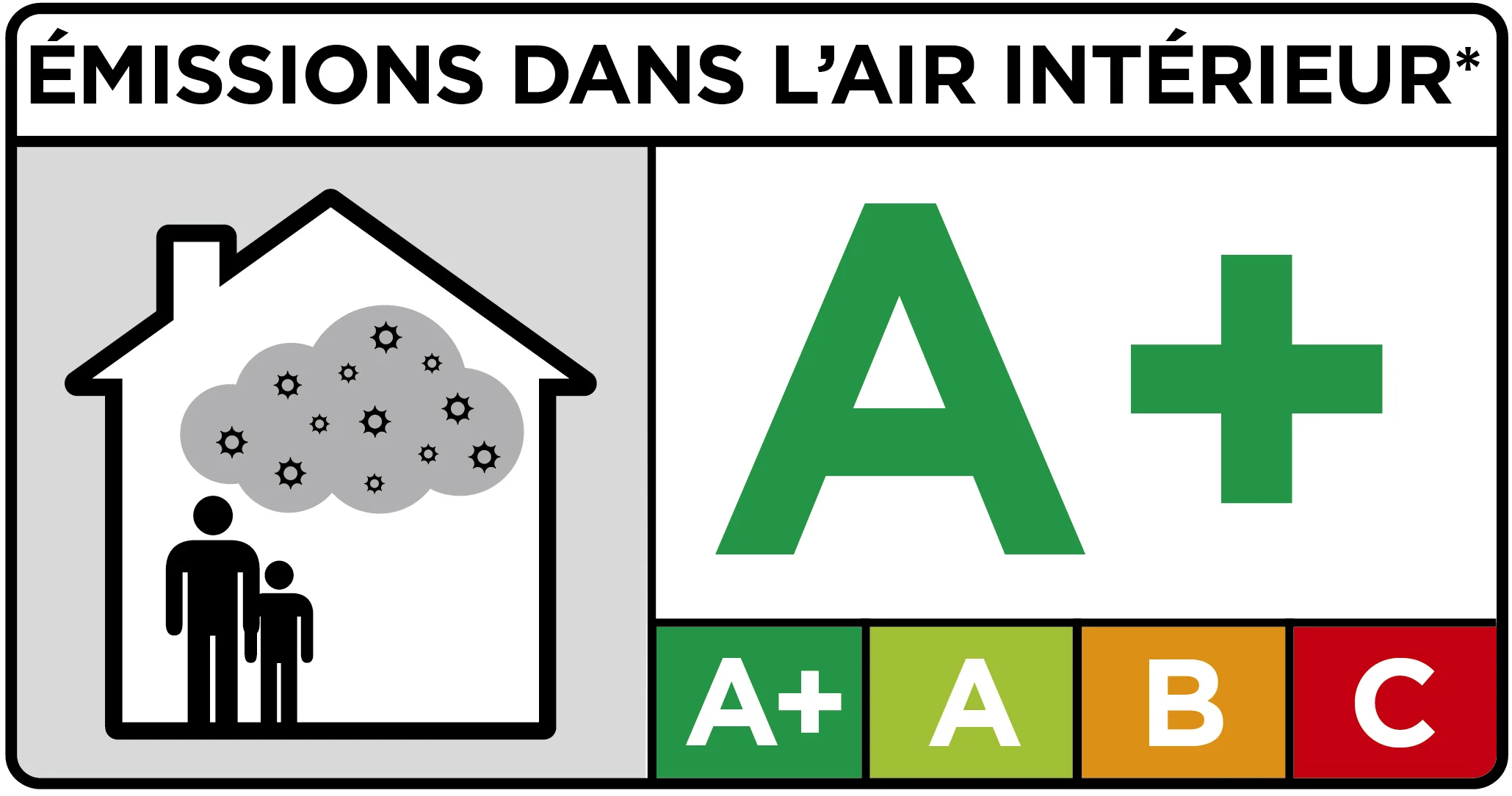

| VOC pronto uso (D.lgs 161/06) | <70g/l Cat.A/j. Pittura bicomponente ad alte prestazioni (BA). |

| Punto di infiammabilità | Non applicabile |

| Solvente per la pulizia attrezzi | Acqua |

| Magazzinaggio | 12 mesi, conservare in luogo asciutto ad una temperatura compresa tra i 5°C ed i 35°C; porre particolare attenzione al componente B, sensibile all’umidità dell’aria |

| DATI APPLICAZIONE E TEMPI | |

|---|---|

| Rapporto di miscela | in peso: A=100, B=16 |

| Diluente consigliato | Acqua (solo dopo la miscelazione dei 2 componenti) |

| Pot-life (50% U.R.) | a 10°C 120-180 min a 25°C 90-120 min a 30°C 60-90 min |

| Secco al tatto (50% U.R.) | a 10°C 12-12 ore a 25°C 3-4 ore a 30°C 2-3 ore |

| Ricopertura (50% U.R.) | a25°C da 4 a 36 ore |

| Trafficabile (50% U.R.) | a 25°C 3-5 giorni |

| Indurimento in profondità (50% U.R.) | a 25°C 7 giorni |

| Condizioni ambientali d’uso | Temperature comprese tra i +10°C e i +30°C e U.R. < 70% |

| Temperatura superficie | Tra i +10°C e i +25°C |

| Manutenzione rivestimento | Per le operazioni di pulizia attendere almeno 7 giorni dall’applicazione del rivestimento e utilizzare solo detergenti neutri |

| DATI TECNICI PRESTAZIONALI | |

|---|---|

| Aspetto | Liscio e omogeneo |

| Gloss 60° | 25-35 Il grado di gloss di FINIWATER SATINATO è influenzato dai seguenti fattori: - porosità del supporto - modalità di miscelazione |

| Scivolosità (D.M. 236/89) | μ>0,40 (con il 3% di SFERETTE DI VETRO FINI) |

| Marcatura CE (reg. n. 305/2011) | Conforme a EN 1504-2. Rivestimento (C) Principio (PR). |

| Adesione Pull Off (EN 1542) | > 1,5 MPa |

| Resistenza all’abrasione norma EN 5470-1 | 25 mg (Taber CS-10; 1000 giri; 1000 gr) 752 mg (Taber H22; 1000 giri; 1000 gr) |

| Resistenza all’urto (EN 6272-1) | >9,8Nm |

| Permeabilità all’acqua (EN 1062-2) | w = 0,039 kg/(h0,5•m2) |