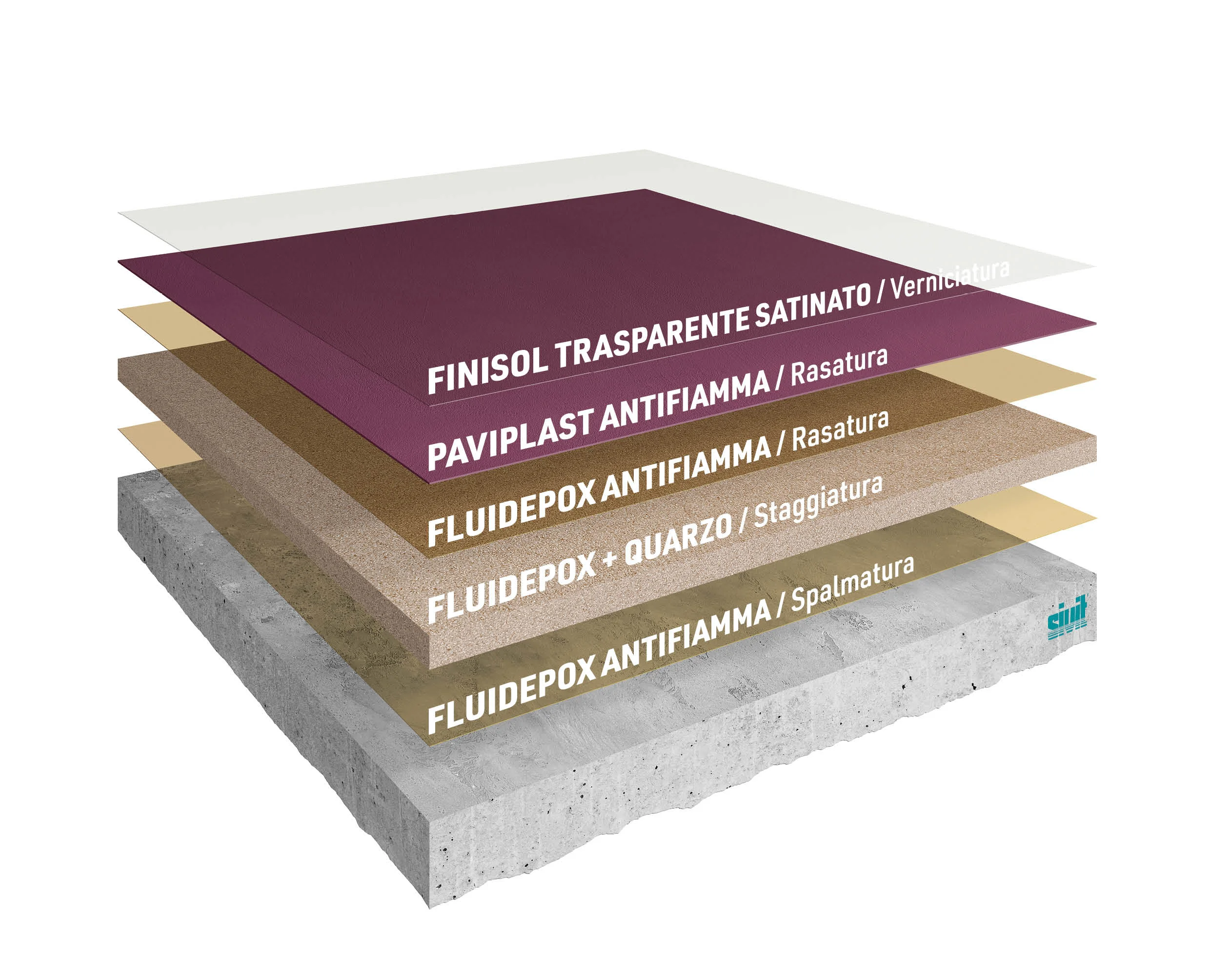

FINISOL® TRASPARENTE SATINATO A+B

Vernice poliuretanica trasparente satinata alifatica a solvente

Vernice poliuretanica bicomponente a base solvente. Idonea per la finitura di rivestimenti resinosi o pavimentazioni in calcestruzzo.

Ottime resistenze meccaniche e chimiche.

Aspetto satinato.

Tipologia: Finiture Poliuretaniche a Base Solvente

Descrizione

Formulato trasparente a base di resine poliuretaniche alifatiche.

FINISOL TRASPARENTE SATINATO forma una pellicola che mantiene buona flessibilità e buona resistenza all'abrasione e al graffio.

Resiste ai raggi ultravioletti grazie a filtri UV che ne prevengono il degrado foto-ossidativo.

Il film indurito resiste all'aggressione di molteplici acidi (per ulteriori dettagli contattare l'Assistenza Tecnica Sivit).

Aspetto satinato.

Utilizzi

Finitura per rivestimenti resinosi.

Verniciatura di pavimenti in calcestruzzo.

Trattamento fiinitura anticorrosivo per strutture in cls. e ferro.

Idoneo in particolare per aree di deposito batterie.

Preparazione del supporto

Ogni supporto deve essere pulito, sgrassato e privo di vecchi rivestimenti in fase di distacco.

Abrasivare superficialmente per favorire l’adesione.

Si consiglia di utilizzare carte abrasive chiare con grana 150 o più fine. Dopo l’abrasione rimuovere completamente la polvere dalla superficie.

- RIVESTIMENTI IN RESINA già esistenti vanno abrasivati o molati, eliminando quindi i residui di polvere. Nel caso di rivestimenti in resina appena realizzati occorre verificare il tempo di ricopertura del prodotto precedentemente applicato.

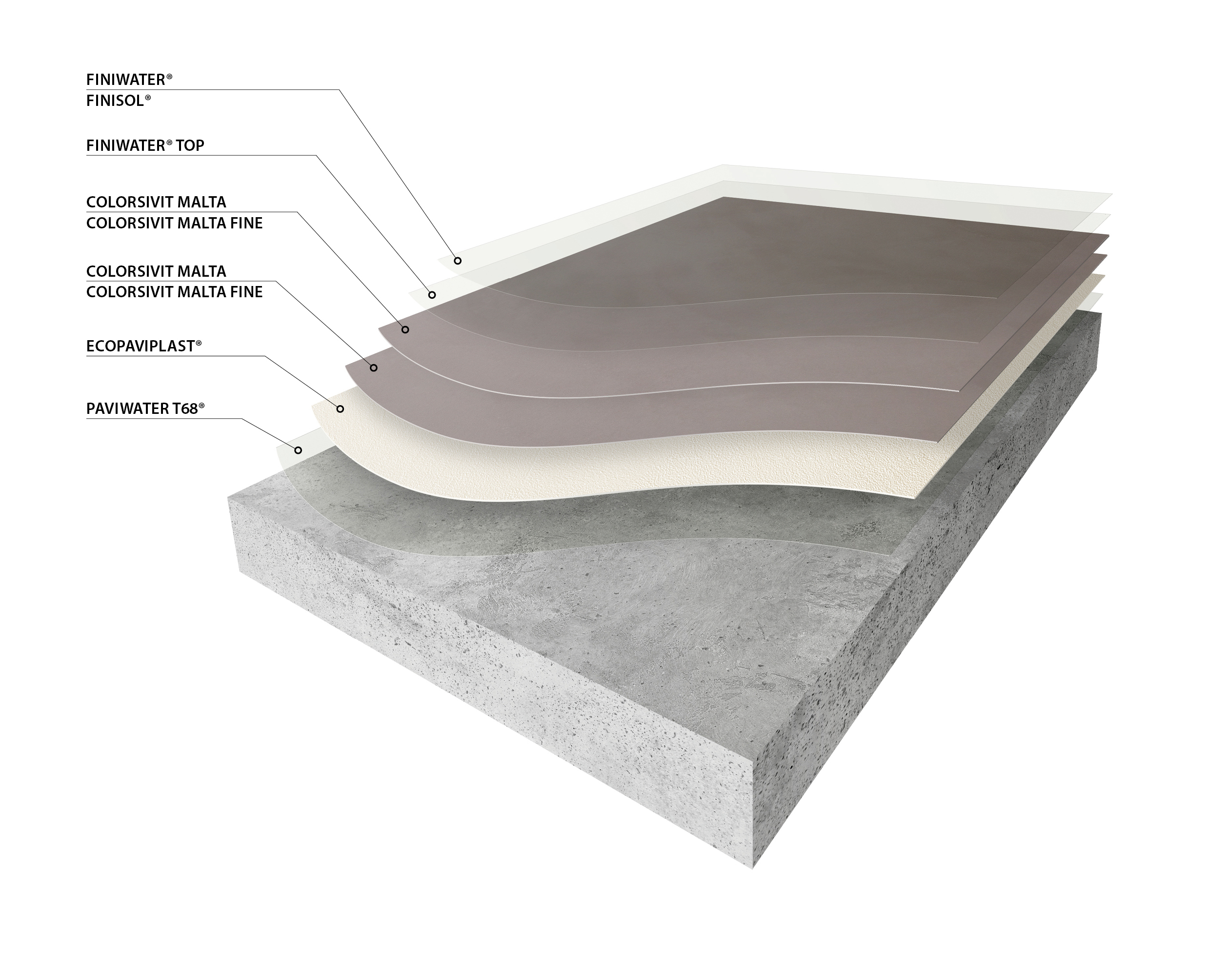

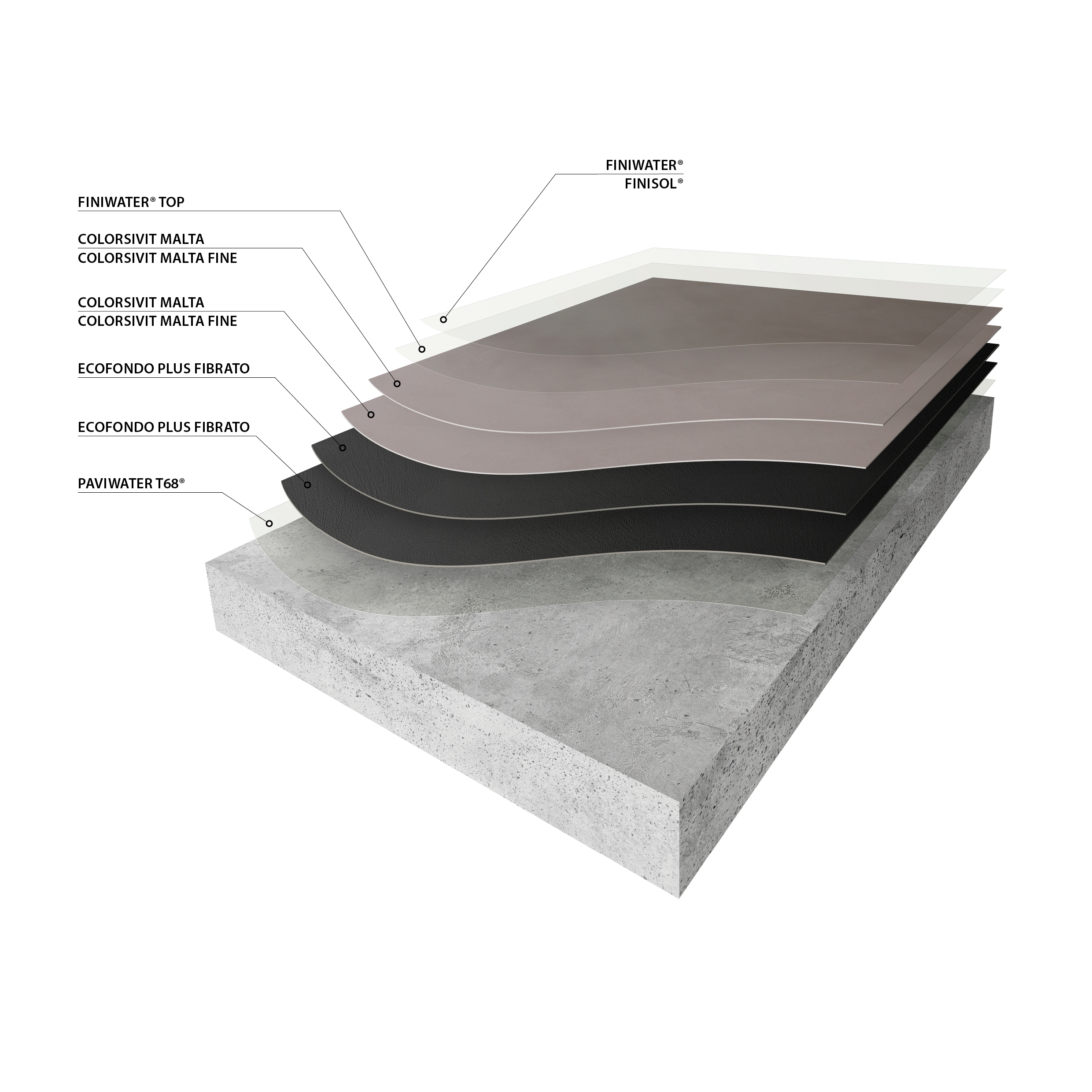

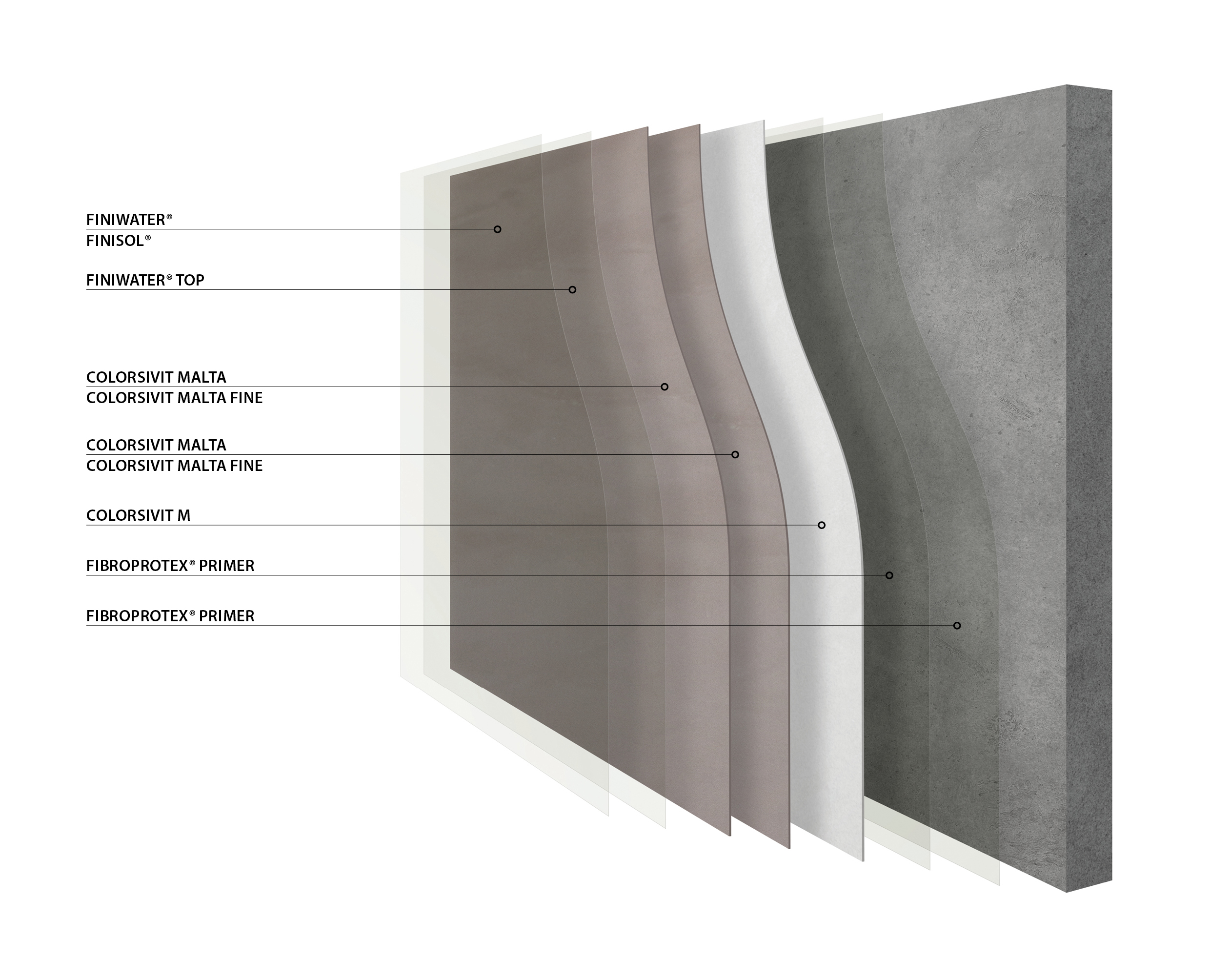

- SUPERFICI IN CLS. E LATERIZI dovranno essere solidi, stagionati, livellati, assorbenti, non inquinati da oli, da polveri o da altre sostanze.

Preparare meccanicamente la superficie mediante carteggiatura o molatura. Primerizzare la superficie mediante l'applicazione di PAVIWATER T68.

Eventuali buchi e lievi anomalie, possono essere riparati con PAVIRAPID o SIVITCOL. - SUPERIFCI METALLICHE applicare un fondo epossidico anticorrosivo previa preparazione meccanica (contattare l’Assistenza Tecnica Sivit).

Applicazione

Unire i due componenti (A+B) e miscelare servendosi di trapano miscelatore per 1 minuto.

Applicare la miscela a rullo con un consumo di circa 0,100 kg/m2.

Per ottenere una superficie ruvida e antisdrucciolevole, occorre aggiungere al momento della preparazione dei 2 componenti il 3-5% di SFERETTE DI VETRO o il 10-20% di QUARZO B0/B1 (vedere tabella).

Evitare di preparare miscele parziali di prodotto per non incorrere in accidentali errori, che potrebbero comportare un mancato o completo indurimento.

In caso di applicazione di una seconda mano effettuare una preventiva carteggiatura.

Attenzione: in virtù della natura di queste tipologie di prodotto si presti particolare attenzione al momento della stesura, al fine di evitare inestetismi come rullate, sormonti, differenze di gloss ecc..

In linea generale si proceda a distribuire la vernice sul supporto in modo omogeneo nella giusta quantità; nel congiungersi con l'area appena verniciata si abbia cura di riprendere la verniciatura a qualche centimetro di distanza in modo da scaricare l'eccesso di prodotto e raccordarsi poi con la precedente area sfumando e dosando la quantità applicata con attenzione. Non attendere troppo per le sovrapposizioni, verniciare sempre “fresco su fresco”.

Nella realizzazione di grandi superfici è necessario il movimento coordinato di diversi applicatori.

L'applicazione del prodotto mediante pennello origina un film con un gloss finale più elevato rispetto all’applicazione a rullo.

Avvertenza: il prodotto contiene solventi, è necessario pertanto che gli applicatori indossino gli idonei dispositivi di protezione respiratoria indicati sulle Scheda di Sicurezza.

Si raccomanda inoltre di compartimentare in modo opportuno le aree di lavoro durante l'applicazione e nelle ore successive.

Durante la fase di evaporazione, la natura dei solventi impiegati può creare odori fastidiosi per i non addetti ai lavori presenti negli ambienti vicini.

Quando penodabile si raccomanda di areare bene i locali.

Note: qualora si debba travasare il componente A dalla sua confezione originale, si mescoli con cura al fine di omogeneizzare gli agenti opacanti eventualmente sedimentati ed ottenere così il valore di gloss nominale

Specifiche tecniche

| DATI PRODOTTO | |

|---|---|

| Colore | Trasparente |

| Consumo | A rullo: circa 0,100 kg/m2 |

| Peso specifico (a 25°C) | miscela (A+B): 1,00 +/- 0,05 g/ml |

| Viscosità (a 25°C) | miscela (A+B) 500 +/- 50 mPa•s (spindle 2, rpm 30) |

| Residuo secco (A+B) | 59-61% in peso |

| VOC pronto uso (D. lgs 161/06) | < 500 g/l Cat. A/j. Pittura bicomponente ad alte prestazioni (BS). |

| Solvente per la pulizia attrezzi | Solvente UNI |

| Magazzinaggio | 12 mesi, conservare in luogo asciutto ad una temperatura compresa tra i 5°C ed i 30°C; porre particolare attenzione al componente B, sensibile all’umidità dell’aria |

| DATI APPLICAZIONE E TEMPI | |

|---|---|

| Rapporto di miscela | in peso: A=100, B=33 |

| Pot-life (50% U.R.) | a 10°C 70 min a 25°C 40 min a 35°C 25 min |

| Secco al tatto (50% U.R.) | a 10°C 20-24 ore a 25°C 12-14 ore a 35°C 8-10 ore |

| Pedonabile (50% U.R.) | a 25°C 12-24 ore |

| Ricopertura (50% U.R.) | a 25°C da 12 a 36 ore (previa carteggiatura) |

| Trafficabile (50% U.R.) | a 25°C 3-5 giorni |

| Indurimento in profondità (50% U.R.) | a 25°C 7 giorni |

| Condizioni ambientali d’uso | Temperature comprese tra i +10°C e i +35°C e U.R. < 60% FINISOL TRASPARENTE SATINATO va applicato ad una temperatura del supporto di almeno 3°C superiore alla temperatura di condensa per evitare problemi di adesione. |

| Manutenzione rivestimento | Per le operazioni di pulizia attendere almeno 7 giorni dall’applicazione del rivestimento |

| DATI TECNICI PRESTAZIONALI | |

|---|---|

| Aspetto | Liscio e omogeneo |

| Gloss 60° | 30-40 Il grado di gloss di FINISOL TRASPARENTE SATINATO è influenzato dai seguenti fattori: - porosità del supporto - spessore del film |

| Gloss 85° (DIN 67530) | 40-70 Il grado di gloss di FINISOL TRASPARENTE SATINATO è influenzato dai seguenti fattori: - porosità del supporto - spessore del film |

| Scivolosità (D.M. 236/89) | µ>0,40 (con il 3% di SFERETTE DI VETRO FINI) |

| Scivolosità (DIN 51130) | R11 (con il 5% di SFERETTE DI VETRO GROSSE) R12 (con il 20% di QUARZO B2) |

| Marcatura CE (reg. n. 305/2011) | Conforme a EN 1504-2. Rivestimento (C) Principio (PR). |

| Adesione Pull Off (EN 1542) | >1,5 MPa |

| Resistenza all’abrasione norma EN 5470-1 | <50 mg (Taber CS-10; 1000 giri; 1000 gr) |

| Resistenza all’usura BCA (EN13892-4) | AR 0,5 |

| Resistenza all’urto (EN 6272-1) | 14 Nm |

| Permeabilità all’acqua (EN 1062-2) | w < 0,1 kg/(h0,5•m2) |