SIVIT STONE PU FAST A+B

Legante poliuretanico bicomponente alifatico per ciottolato drenante

Formulato poliuretanico bicomponente da utilizzare come legante per graniglia decorativa per la realizzazione di stone carpet.

I rivestimenti così realizzati sono idonei per l'esterno, drenanti e resistenti all'ingiallimento ed agli agenti atmosferici.

Tipologia: Prodotti per Esterni

Descrizione

Formulato poliuretanico completamente esente da solventi idoneo per essere miscelato con graniglia decorativa nella realizzazione di rivestimenti e pavimentazioni, anche carrabili, ad effetto drenante, in interno o esterno.

Possono essere ottenuti spessori tra 1 e 3 cm.

Nel tempo si sviluppano elevate resistenze meccaniche senza ingiallimenti o degrado da agenti atmosferici.

Rapido sviluppo della resistenza all'acqua.

Lunga shelf life.

Utilizzi

Rivestimenti in graniglia decorativa con spessori di circa 10-12 mm. Es. terrazze, camminamenti, locali civili, ecc.

Rivestimenti in graniglia decorativa carrabili con spessori di circa 24-30 mm. Es. piazzali, piccoli parcheggi ecc.

Supporto

Il supporto al momento dell'applicazione non deve essere bagnato o umido.

Non devono essere presenti buche, irregolarità o avvallamenti.

Garantire le opportune pendenze per favorire il drenaggio.

Preparazione del supporto

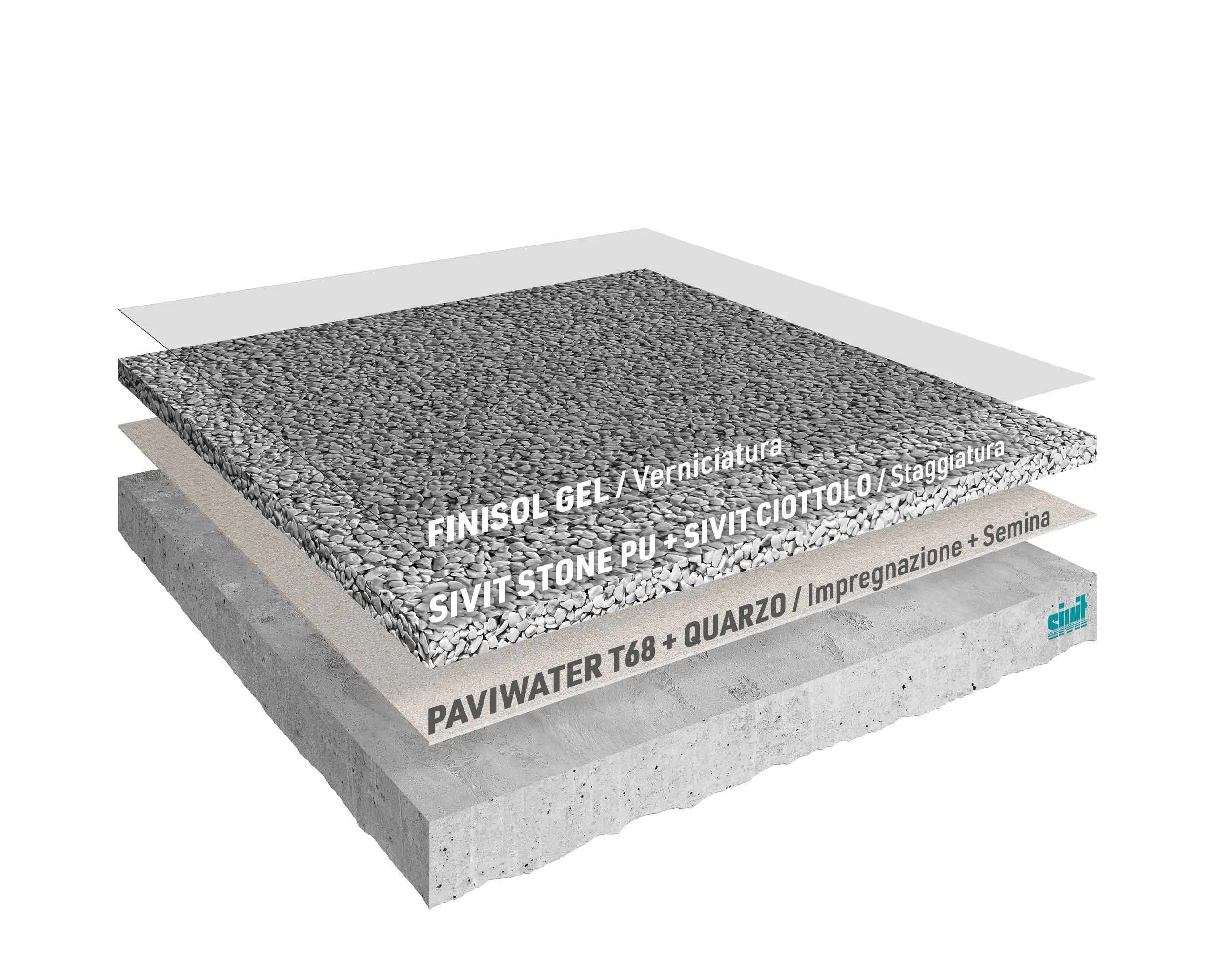

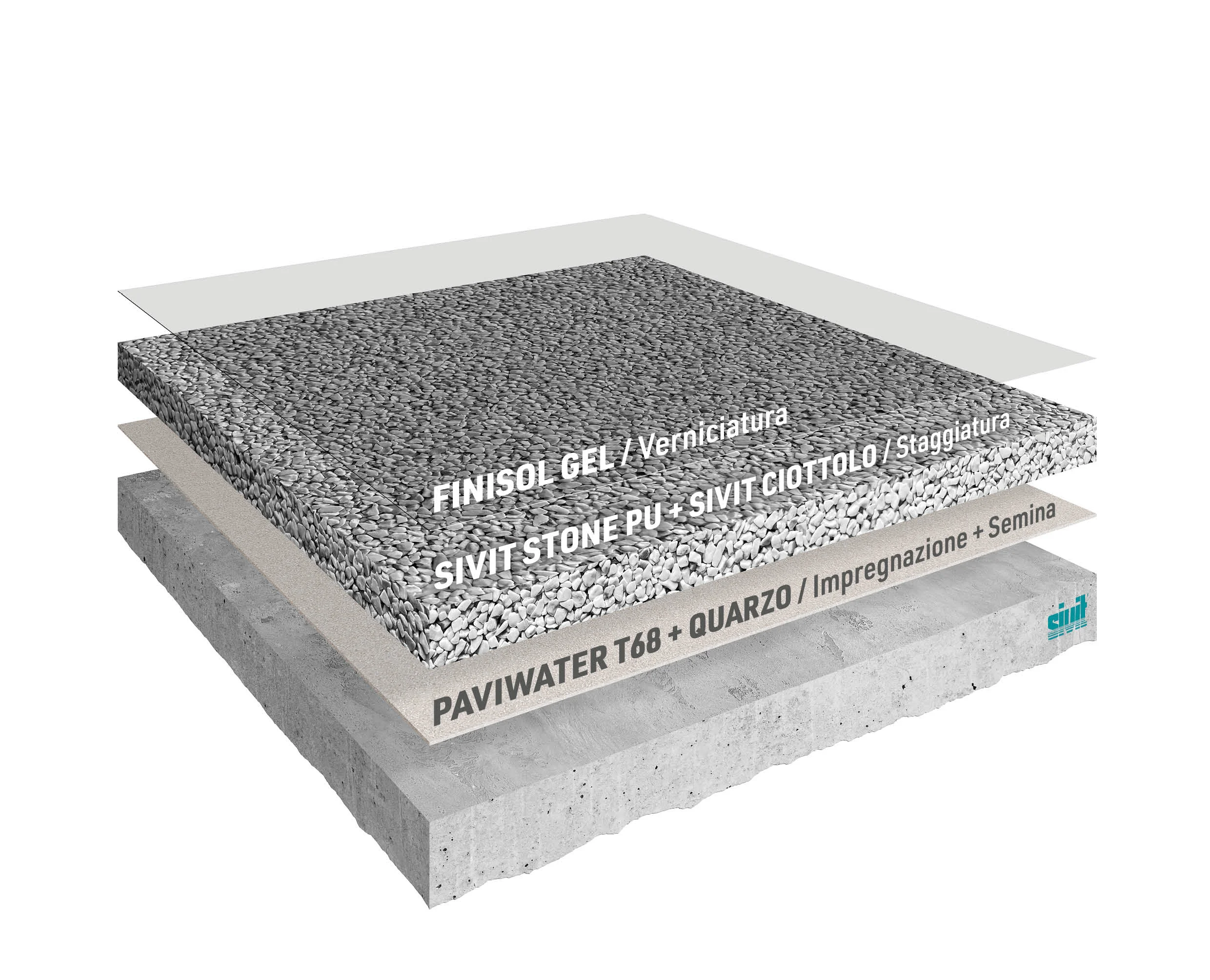

Superfici cementizie spolveranti o molto assorbenti devono essere trattate applicando una mano di PAVIWATER T68 diluito 1:3 con acqua.

Diversamente applicare PAVIWATER T68 diluito 1:0,5 con acqua e spolverato fresco su fresco con QUARZO RESINATO B1 a rifiuto, avendo cura di eliminare l'eccesso ad indurimento avvenuto.

Applicazione

Delimitare la superficie da rivestire utilizzando opportuni profili forati, di altezza pari allo spessore finale che si vuole ottenere.

Preparazione miscela (A+B).

Agitare con cura il componente B accelerante prima dell'utilizzo. Versarlo all'interno del componente A miscelando poi con trapano a basso numero di giri facendo attenzione ad omogeneizzare completamente tutto il materiale; non inglobare troppa aria durante questa fase.

Preparazione impasto.

Impastare la miscela A+B con ciottoli asciutti servendosi di una betoniera o attrezzatura similare.

Si consigliano ciottoli di granulometria 2-4 mm per i quali occorre una percentuale di resina compresa tra il 5 e 6% in peso. Continuare la miscelazione per qualche minuto fino a che la graniglia sia bagnata in modo omogeneo.

N.B. Qualora possa essere presente umidità durante la preparazione o l'applicazione del sistema si consiglia di mantenere la percentuale di resina compresa tra il 4 e 5% in peso.

Applicazione.

Versare l'impasto a terra e distribuirlo mediante frattazzo e staggia; si consiglia l'utilizzo di tondini metallici come quida su cui fare scorrere la staggia, aventi diametro pari allo spessore da ottenere.

Compattare e lisciare la superficie con il frattazzo in modo da non lasciare vuoti o irregolarità.

Nel caso si voglia ulteriormente favorire lo scorrimento della spatola, mantenerla inumidita con solvente per poliuretani, non utilizzare alcol o prodotti a base acqua.

Per ulteriore protezione applicare una mano di finitura poliuretanica FINISOL GEL. Nel caso si volesse aumentare il grip superficiale aggiungere alla finitura 5% di SFERETTE DI VETRO GROSSE o 10% di QUARZO RESINATO B1.

Attenzione. L'applicazione di un'eccessiva quantità di finitura potrebbe compromettere le proprietà drenanti del rivestimento.

Avvertenze

Nella realizzazione di rivestimenti drenanti è fondamentale che il piano di posa sia planare e dotato delle opportune pendenze per fare defluire l'acqua.

E' necessario verificare che i ciottoli non abbiano assorbito umidità durante lo stoccaggio e risultino pertanto perfettamente asciutti al momento dell'impasto.

Specifiche tecniche

| DATI PRODOTTO | |

|---|---|

| Colore | Trasparente |

| Consumo | Per spessore 1,2 cm: circa 20kg di ciottoli (2-4mm) e 1,0-1,2 kg di resina |

| Peso specifico (a 25°C) | 1,15 +/- 0,05 g/ml |

| Viscosità (a 25°C) | Comp.A 1000-1100 mPa•s Comp.B 10-12 sec (Coppa F4) A+B 600-800 mPa•s |

| Solvente per la pulizia attrezzi | Solvente UNI |

| Magazzinaggio | 6 mesi, conservare in luogo asciutto negli imballaggi originali sigillati, ad una temperatura compresa tra 5° - 30°C; il prodotto è estremamente sensibile all’umidità dell’aria. |

| DATI APPLICAZIONE E TEMPI | |

|---|---|

| Rapporto di miscela | 4-6% di resina (legante + accelerante) sul peso di ciottoli con granulometria 2-4 mm. |

| Pot-life (50% U.R.) | A+B: a 25°C 24-48 ore Impasto: a 25°C 2-3 ore |

| Secco al tatto (50% U.R.) | a 25°C 4-6 ore |

| Pedonabile (50% U.R.) | a 25°C 8-10 ore |

| Trafficabile (50% U.R.) | a 25°C 3-5 giorni |

| Completo sviluppo resistenze meccaniche | a 25°C 3-5 giorni |

| Condizioni ambientali d’uso | Temperature comprese tra i +10°C e i +35°C e U.R. < 60% |

| DATI TECNICI PRESTAZIONALI | |

|---|---|

| Aspetto | Lucido |

| Resistenza a compressione (UNI EN 196-1) | >7 N/mm2 |