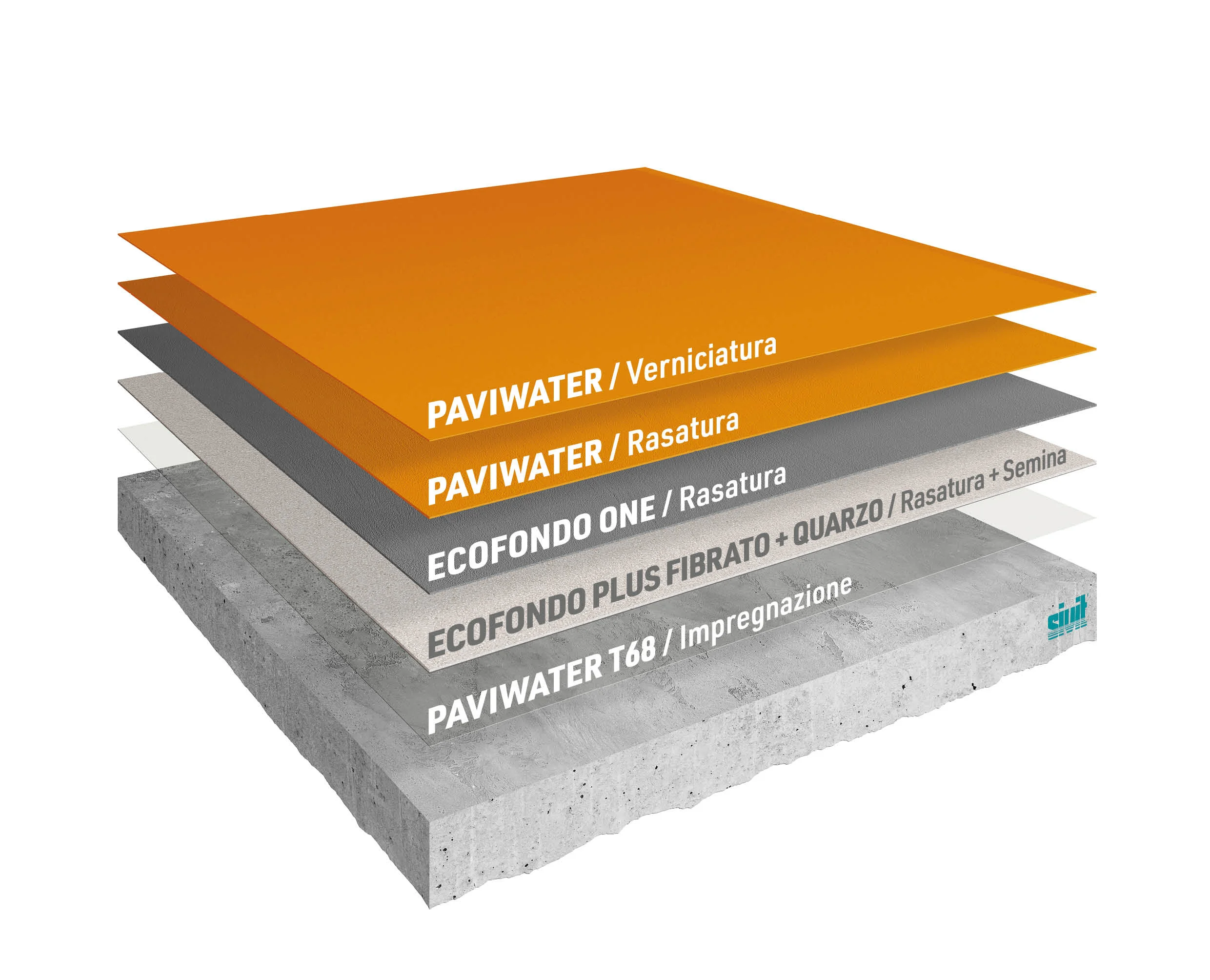

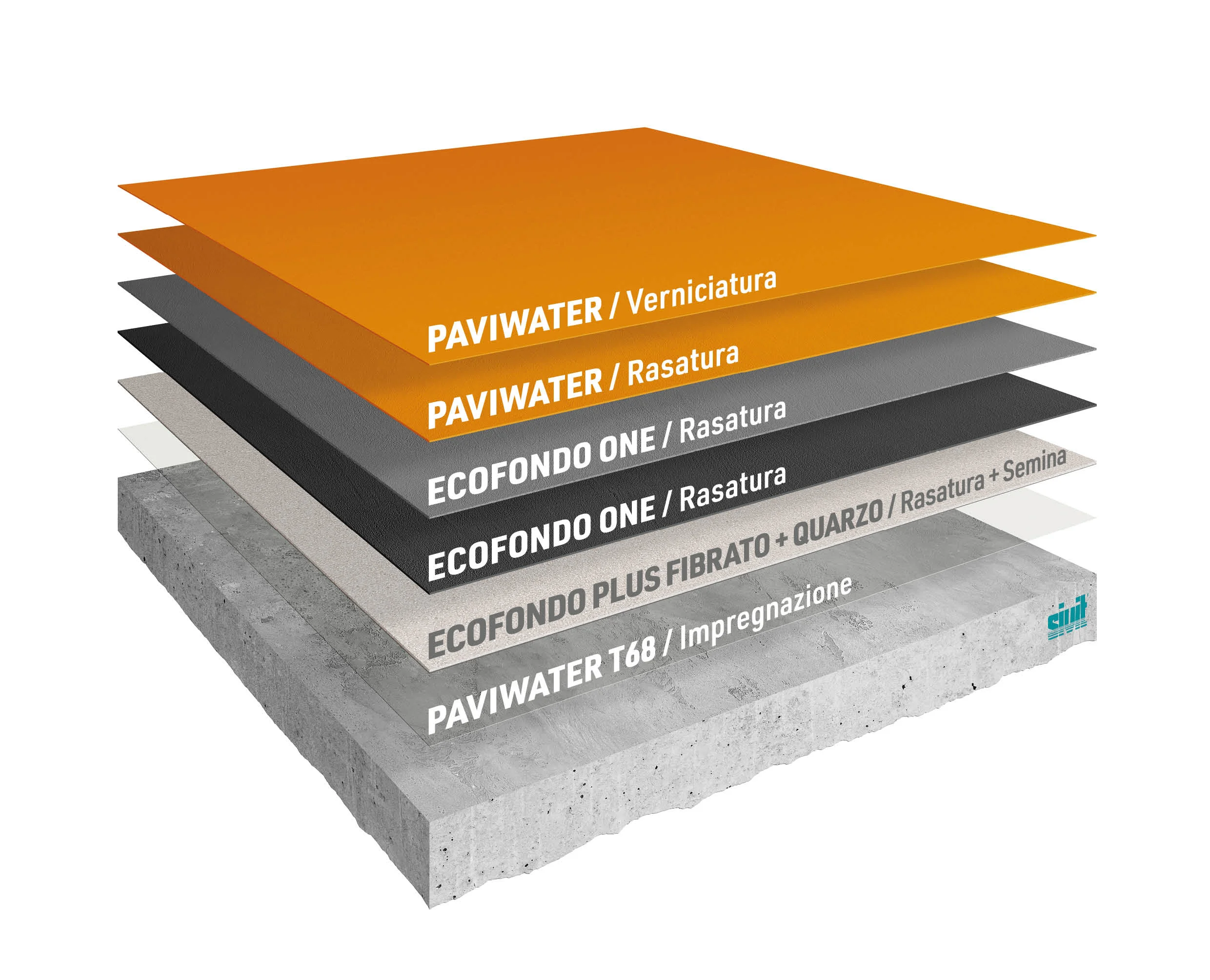

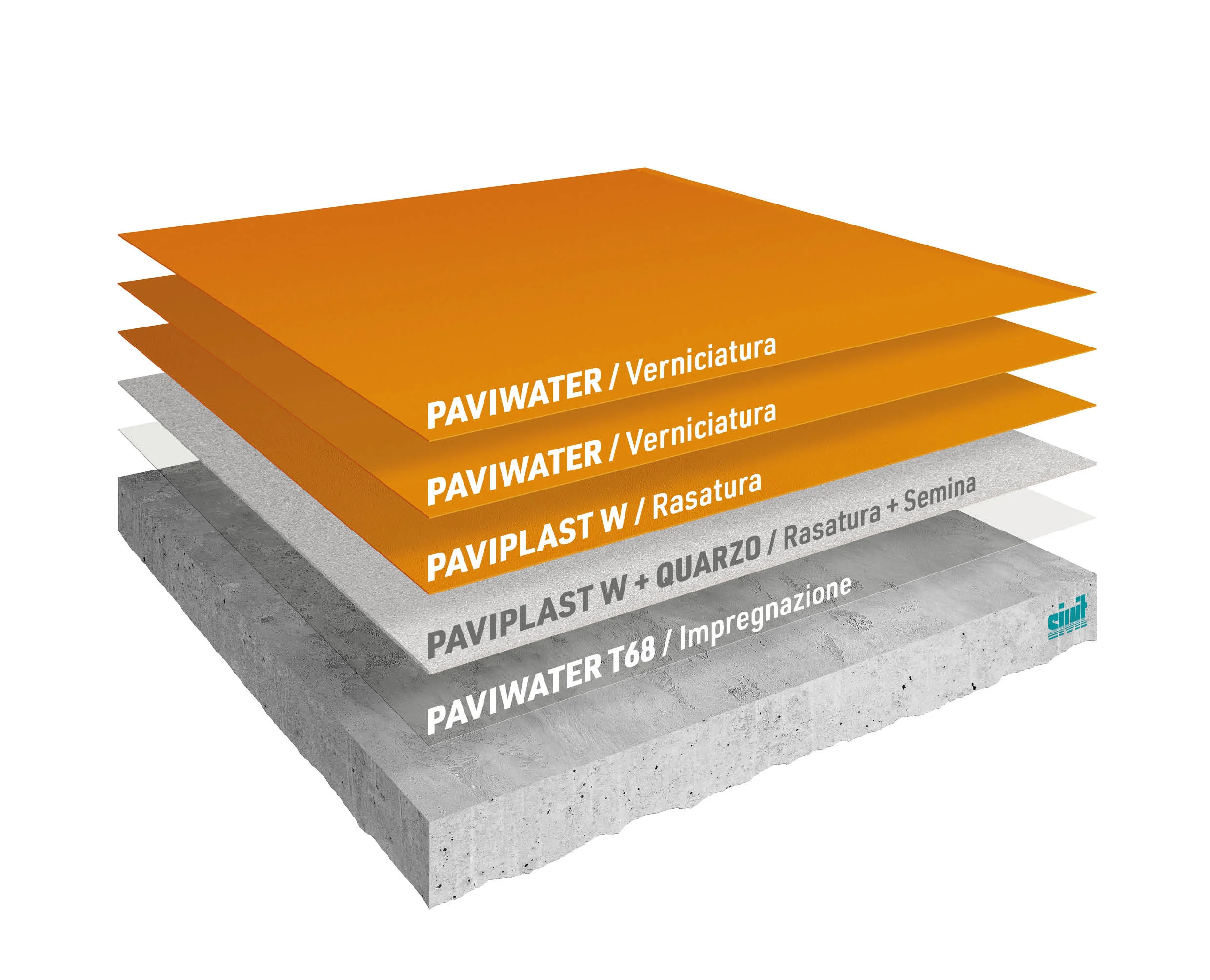

PAVIWATER® T68 A+B

Trasparente epossidico in emulsione acquosa

Diluibile in acqua per ridurne la viscosità, Paviwater T68 consente di ottenere una pellicola con buone caratteristiche meccaniche, resistente a oli, grassi, saponi, detergenti e agenti atmosferici. Il prodotto è molto versatile: può essere utilizzato come primer per rivestimenti in resina, finitura trasparente su pavimentazioni interne, impregnante antipolvere per superfici in cemento. Si può utilizzare anche per la realizzazione di rivestimenti rinforzati con fibra di vetro.

Tipologia: Fondi, Consolidanti, Primer

Descrizione

Sistema epossidico bicomponente, a base di resine epossidiche ed amminiche in dispersione acquosa. Il prodotto viene fornito con un alto contenuto di solidi: la viscosità può essere abbassata sensibilmente diluendo con acqua. La pellicola che si ottiene presenta buone caratteristiche meccaniche e buone resistenze ai solventi.

Utilizzi

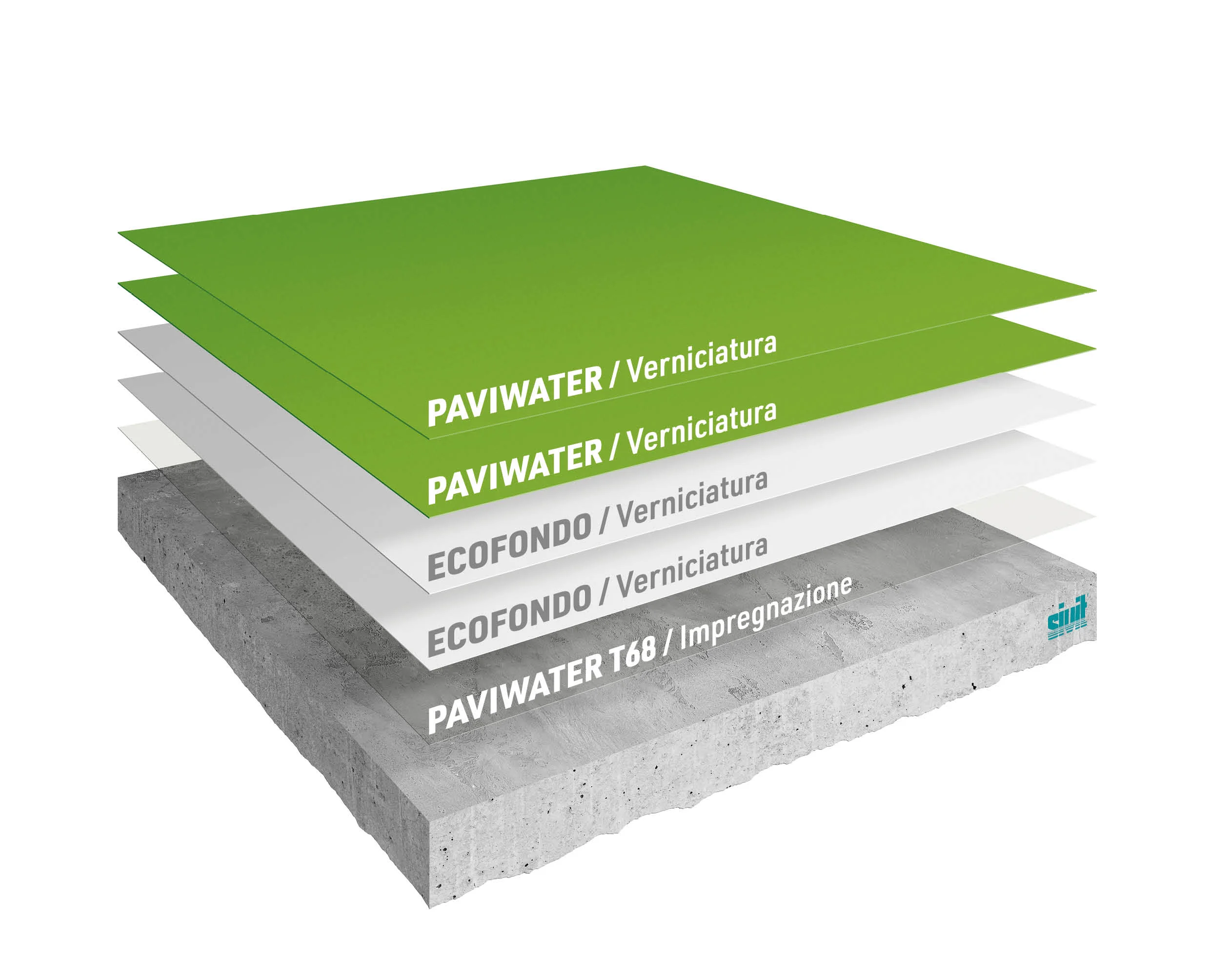

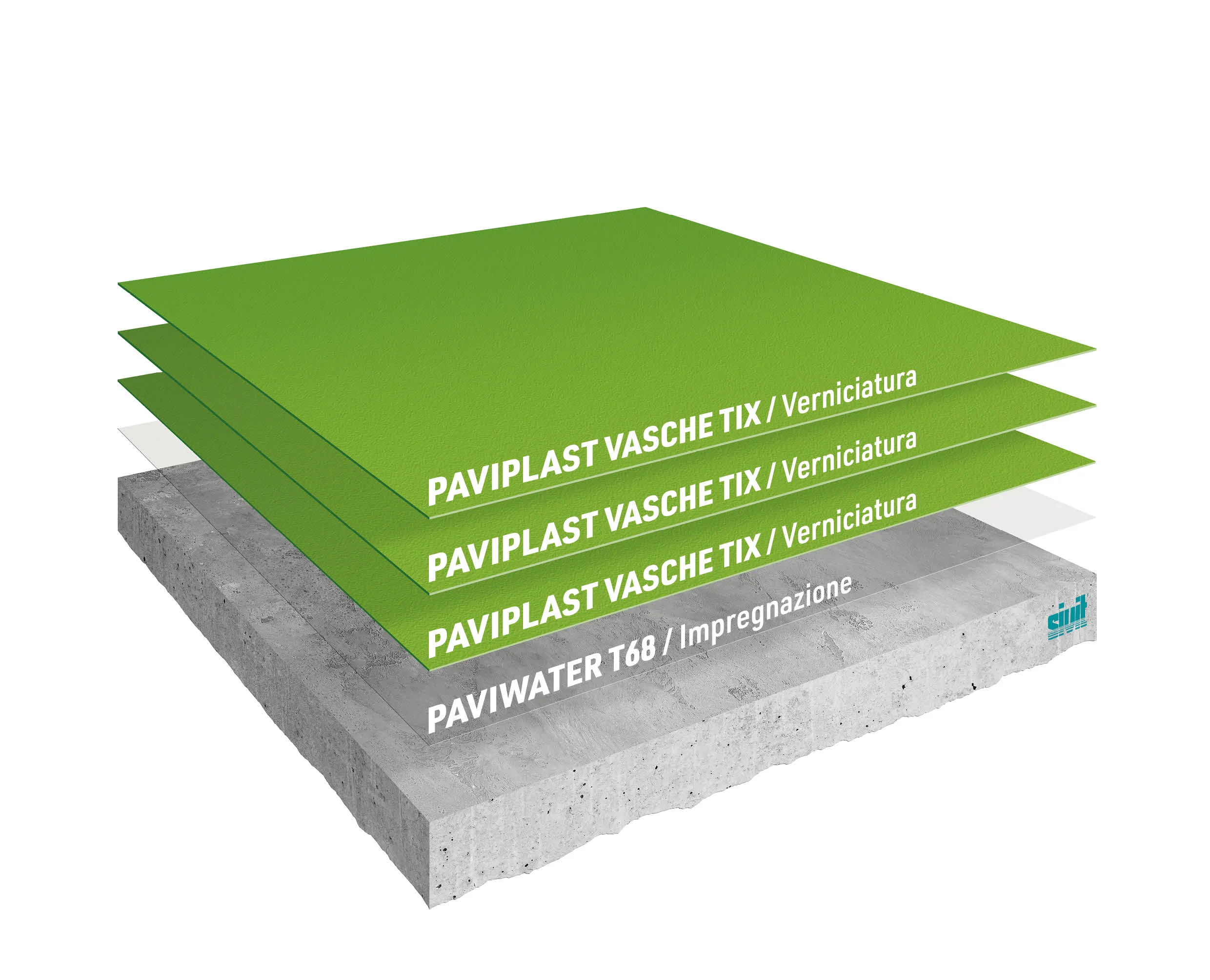

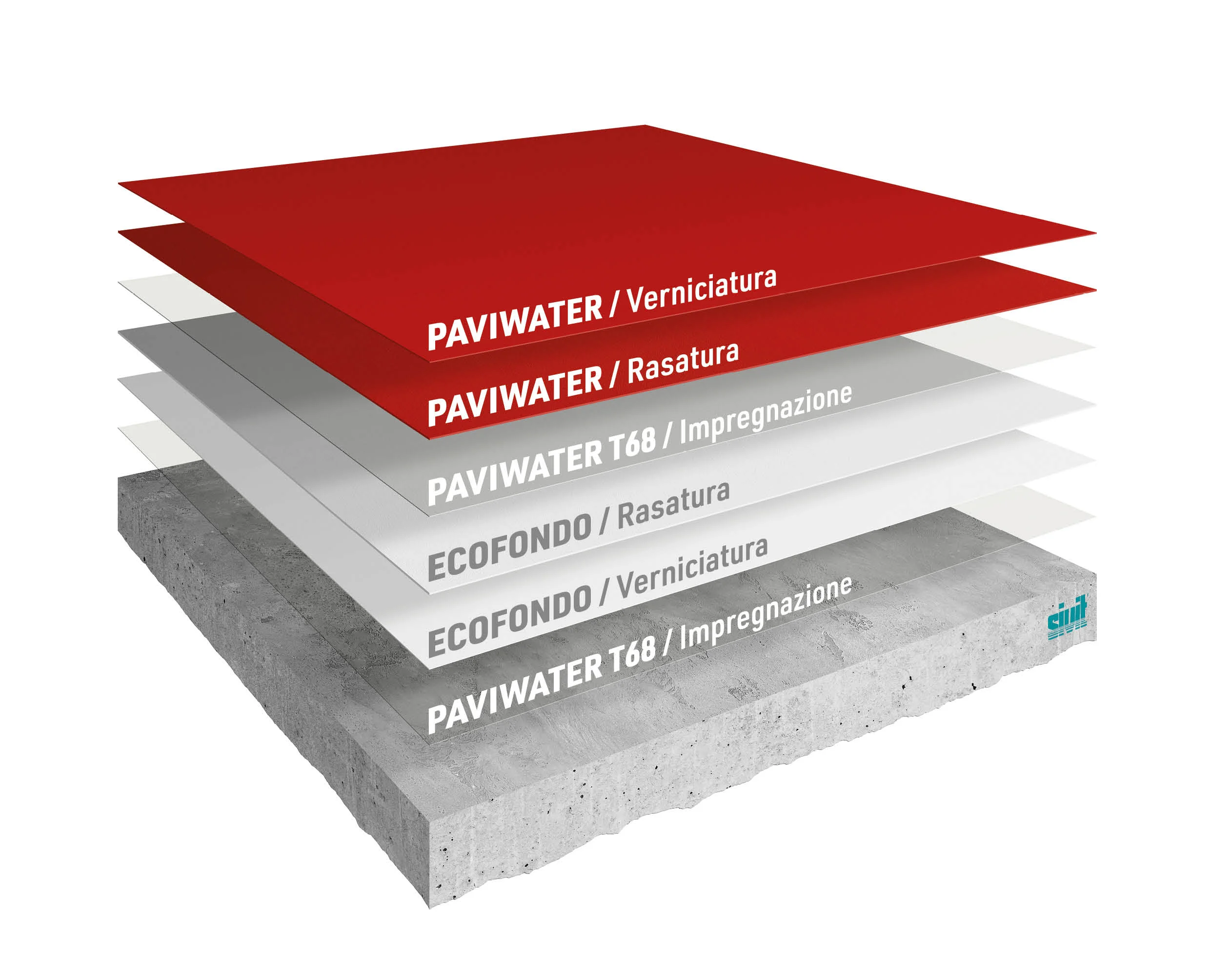

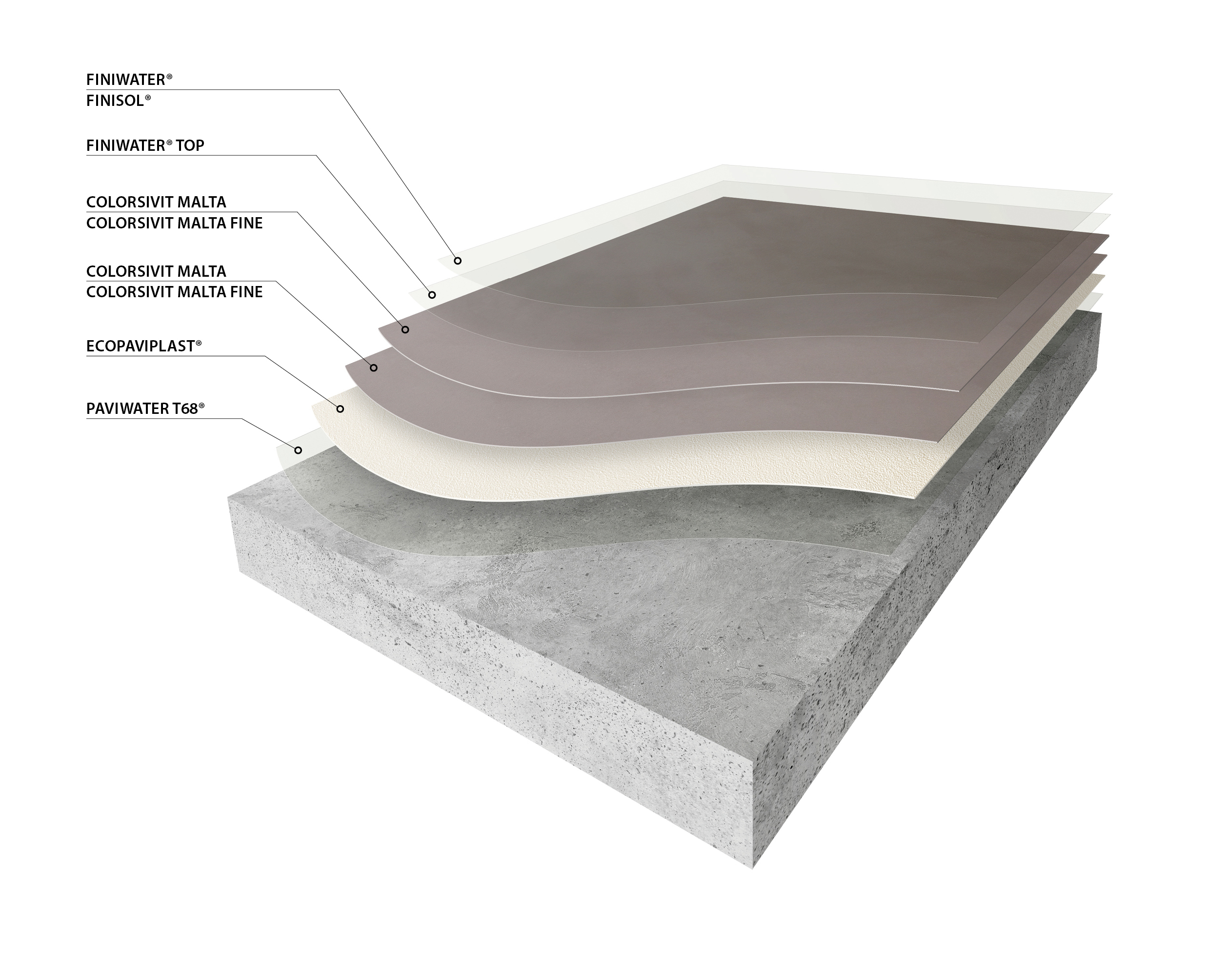

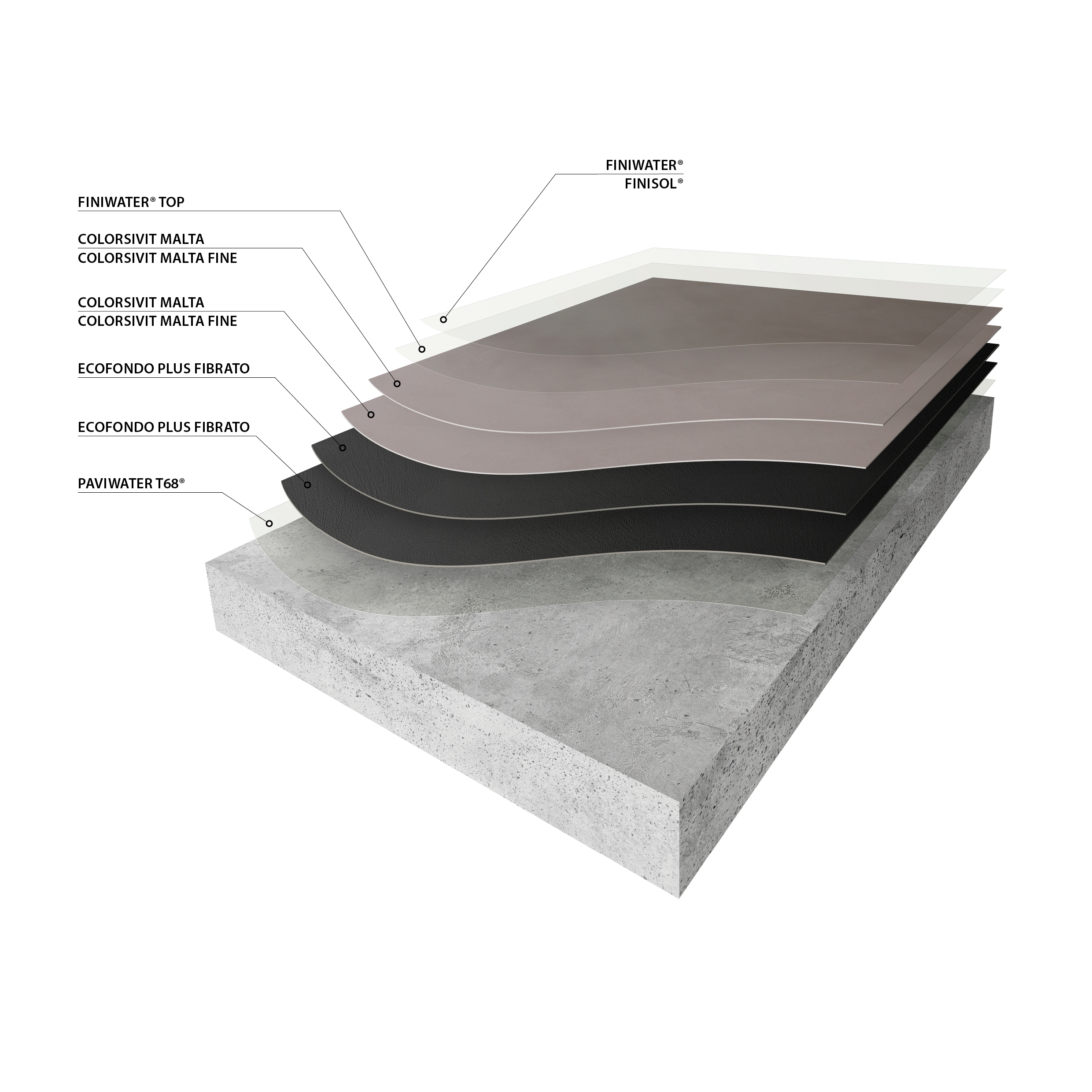

Impregnante antipolvere per superfici cementizie.

Consolidante per superfici cementizie friabili.

Primer per rivestimenti resinosi.

Primer per sistemi impermeabilizzanti a base di poliurea su supporti in guaina bitume-polimero e asfalto.

Realizzazione di rivestimenti rinforzati con fibra di vetro.

Supporto

Il sottofondo deve possedere una resistenza minima alla compressione di 25 N/mm2 e a trazione di 1,5 N/mm2

Preparazione del supporto

Se il cls è di nuova costruzione si dovrà attendere la maturazione completa. La superficie si dovrà presentare solida, assorbente ed esente da presenza di oli, tensioattivi, acqua, polvere. Eventuali parti inconsistenti dovranno essere rimosse.

Le pavimentazioni vanno trattate meccanicamente, mediante carteggiatura. Eventuali buchi e lievi anomalie, possono essere riparati con PAVIRAPID o SIVITCOL.

Applicazione

Al momento dell’applicazione unire i due componenti in un unico recipiente e miscelare con cura per 2 minuti, utilizzando adeguata attrezzatura (trapano con elica). Aggiungere lentamente sotto agitazione l’acqua di diluizione, rimescolare il prodotto per 1 minuto ed utilizzare entro il tempo di utilizzo.

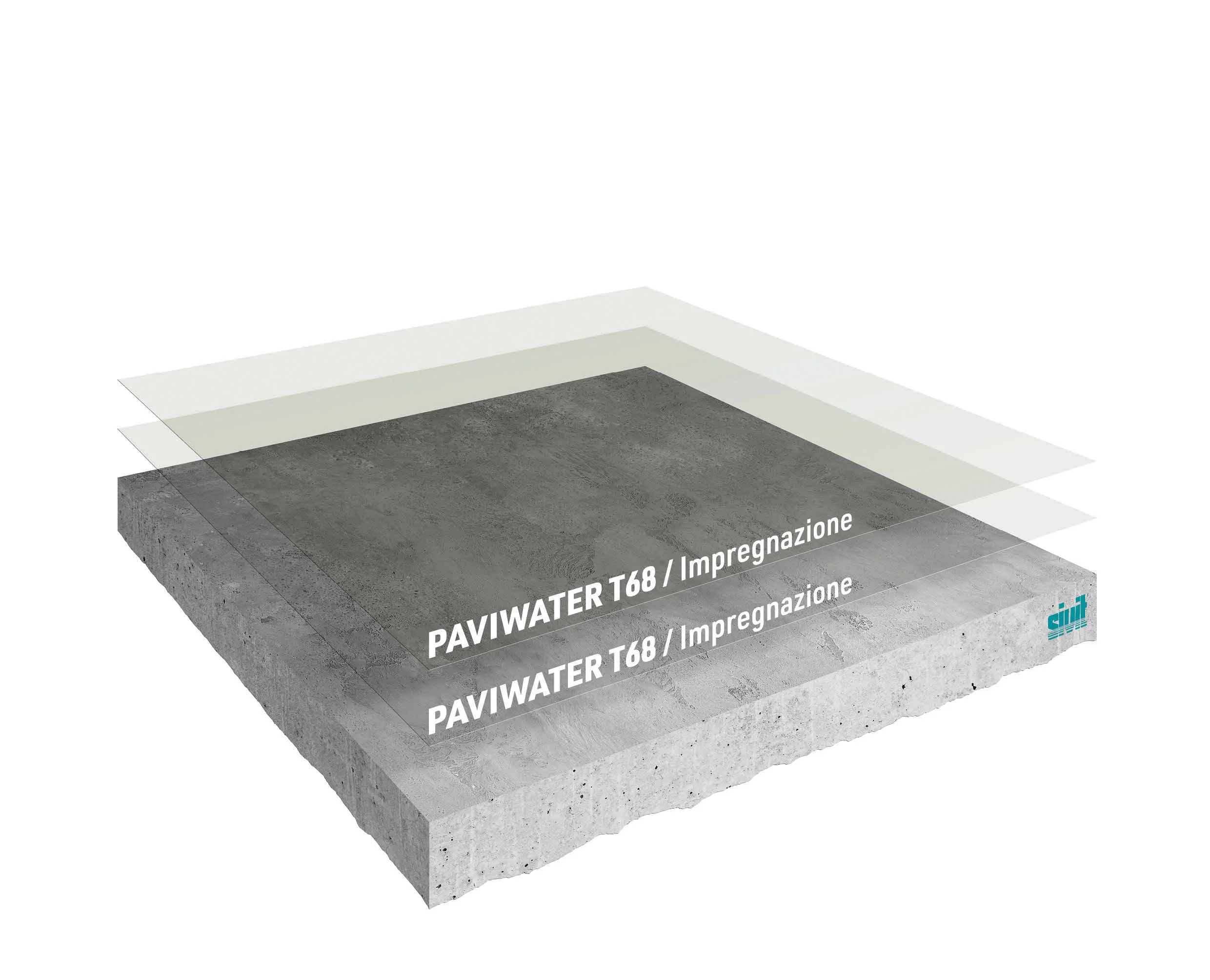

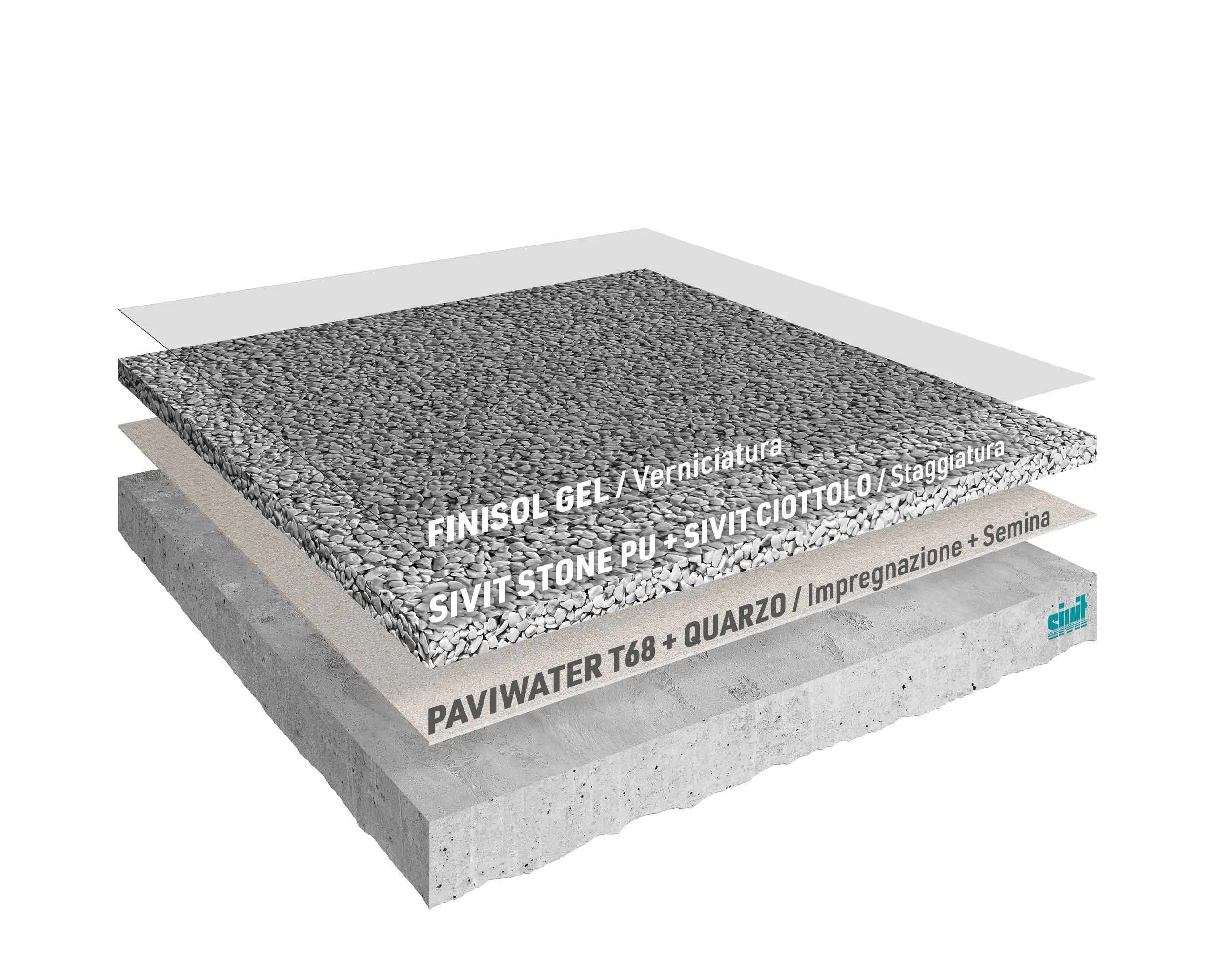

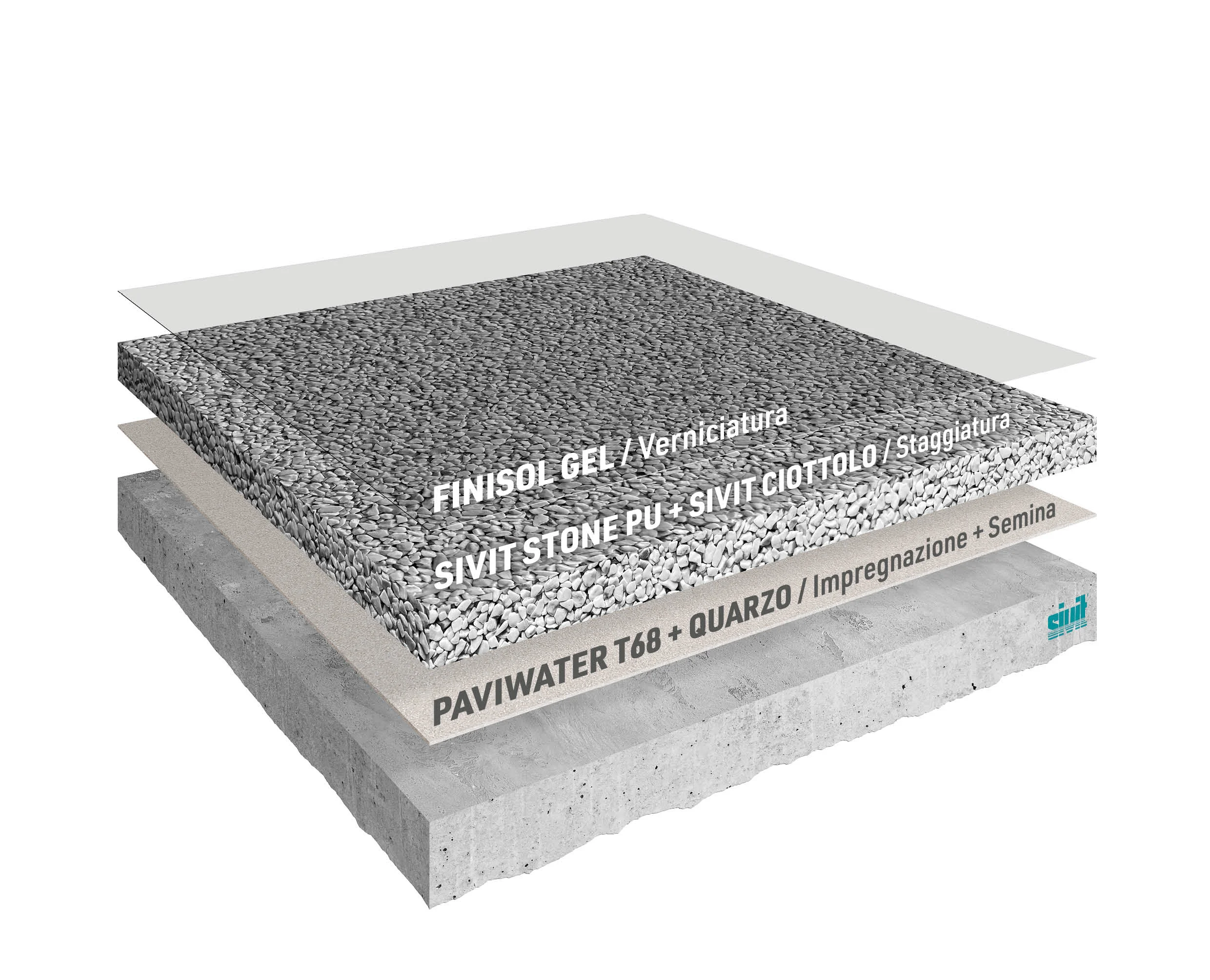

Primer impregnante e consolidante per superfici cementizie: applicare due riprese per un consumo di prodotto di circa 50 g/m2 (per ciascuna ripresa):

- 1° ripresa - una parte (A+B) + 3 parti di acqua

- 2° ripresa - una parte (A+B) + 1,5 parti di acqua

Primer per sistemi impermeabilizzanti a base di poliurea su supporti in guaina bitume-polimero o in asfalto: applicare una parte di prodotto (A+B) + 0,5 parti di acqua, per un consumo orientativo di prodotto compreso tra 0,10 e 0,20 kg/m2 in funzione delle caratteristiche del supporto. Sul primer ancora fresco semina a rifiuto di QUARZO B1 con un consumo di 1-2 Kg/m2 , avendo cura il giorno successivo di eliminare il quarzo in eccesso non legato.

Legante per realizzare rivestimenti in vetroresina (con MAT 225): applicare una parte di prodotto (A+B) + 0,2 parti di acqua, per un consumo di prodotto di 0,70 kg/m2; il ciclo dovrà essere successivamente completato per realizzare pavimentazioni o rivestimenti impermeabilizzanti

Avvertenze

Prodotto ad uso professionale, l’acquirente si impegna a seguire tassativamente le avvertenze sopra riportate nell’applicazione del prodotto acquistato e le indicazioni della scheda di sicurezza.

Specifiche tecniche

| DATI PRODOTTO | |

|---|---|

| Colore | Trasparente giallognolo |

| Consumo | Come impregnante, 0,050 kg/m2 per ripresa, in funzione dell’assorbimento. Con spolvero di quarzo, 0,08-0,20 kg/m2. |

| Peso specifico (a 25°C): miscela (A+B) | 1,10 +/- 0,05 g/ml |

| Viscosità (a 25°C): miscela (A+B) - diluito con 1,5 parti di acqua - diluito con 3 parti di acqua |

10.000 +/- 1.000 mPas (spindle 3, rpm 10) - 5 s (DIN 8) - 3 s (DIN 8) |

| Residuo secco (A+B) | 66-68% in peso |

| VOC pronto uso (D.lgs 161/06) | 50 g/l Cat.A/j. Pittura bicomponente ad alte prestazioni (BA). |

| Punto di infiammabilità | Non applicabile |

| Solvente per la pulizia attrezzi | Acqua |

| Magazzinaggio | 12 mesi, conservare in luogo asciutto ad una temperatura compresa tra i 5°C ed i 35°C |

| DATI APPLICAZIONE E TEMPI | |

|---|---|

| Rapporto di miscela | in peso: A=100, B=67 |

| Pot-life (50% U.R.) | a 15°C > 130 min a 25°C 105 min a 30°C > 80 min |

| Secco al tatto (50% U.R.) | a 10°C 22-26 ore a 25°C 4-6 ore a 30°C 2,5-3,5 ore |

| Ricopertura (50% U.R.) | a 25°C da 4 a 6 ore |

| Indurimento in profondità (50% U.R.) | a 25°C - 7 giorni |

| Condizioni ambientali d’uso | Temperature comprese tra i +15°C e i +35°C e U.R. < 70% |

| Manutenzione rivestimento | Per le operazioni di pulizia utilizzare detergenti neutri |

| DATI TECNICI PRESTAZIONALI | |

|---|---|

| Aspetto | Trasparente |

| Resistenza all’abrasione norma UNI 8298-9 | 60 mg (TABER Mola CS-17-1000 giri -1000 g di peso) |

| Marcatura CE (reg. n. 305/2011) | Conforme a EN1504-2 Rivestimento(C) Principi (PR) |

| Adesione Pull Off (EN 1542) | >1,5 MPa |

| Resistenza all'abrasione norma EN 5470-1 | Conforme |

| Resistenza all'urto (EN 6272-1) | >10 Nm (Classe 2) |

| Permeabilità all’acqua (EN 1062-2) | w < 0,0152 kg/(h0,5*m2) |