PAVIPLAST® A+B

Formulato epossidico autolivellante colorato privo di solvente

Si può applicare a rullo per realizzare rivestimenti antiscivolo e verniciature ad alto spessore impermeabili e antiscintilla.

In alternativa, a Paviplast si possono aggiungere materiali inerti come il quarzo per aumentare la resistenza a impatti e abrasione.

È utilizzato per rendere impermeabili canaline e vasche, per i pavimenti di industrie meccaniche, alimentari, chimiche, depositi e magazzini, laboratori e ospedali, showroom o appartamenti.

Tipologia: Formulati Epossidici

Descrizione

Prodotto bicomponente a base di resine epossidiche e indurenti amminici cicloalifatici, per la realizzazione di rivestimenti autolivellanti, rasature e multistrati.

In alternativa, PAVIPLAST è caricabile con quarzo per applicazioni a rasare. Il formulato è fornito in versione già colorata per alcune tinte o in versione non pigmentata con a parte COLORPASTA EPOX.

Utilizzi

Pavimentazioni di industrie meccaniche, alimentari e chimiche, di depositi e magazzini, di laboratori ed ospedali, di negozi, showroom ed appartamenti.

Supporto

Il sottofondo deve possedere una resistenza minima alla compressione di 25 N/mm2 e a trazione di 1,5 N/mm2.

Preparazione del supporto

Fondi in cls. dovranno essere solidi, asciutti (stagionati se di nuova costruzione), livellati, assorbenti, non inquinati da oli, detergenti, polveri od altre sostanze.

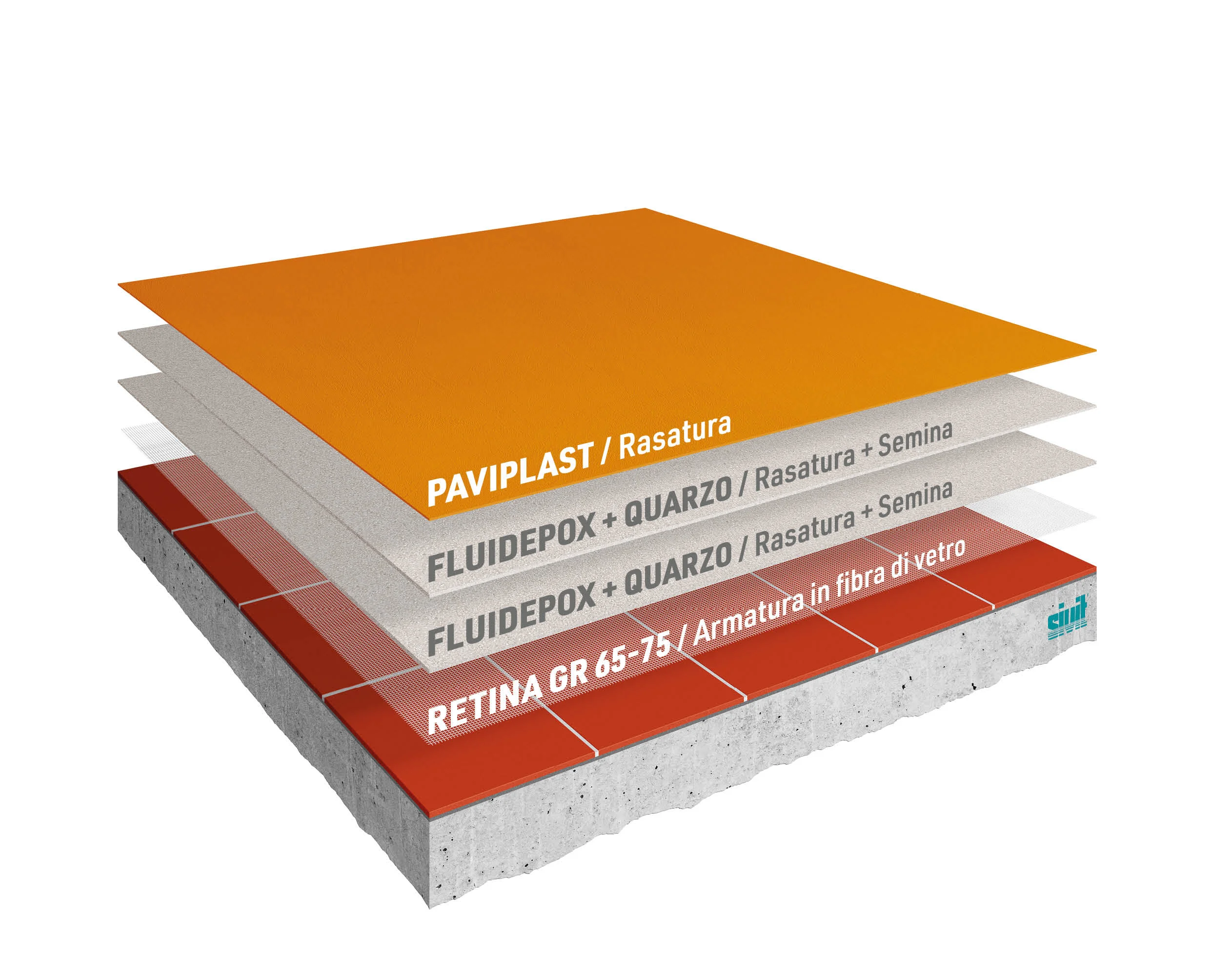

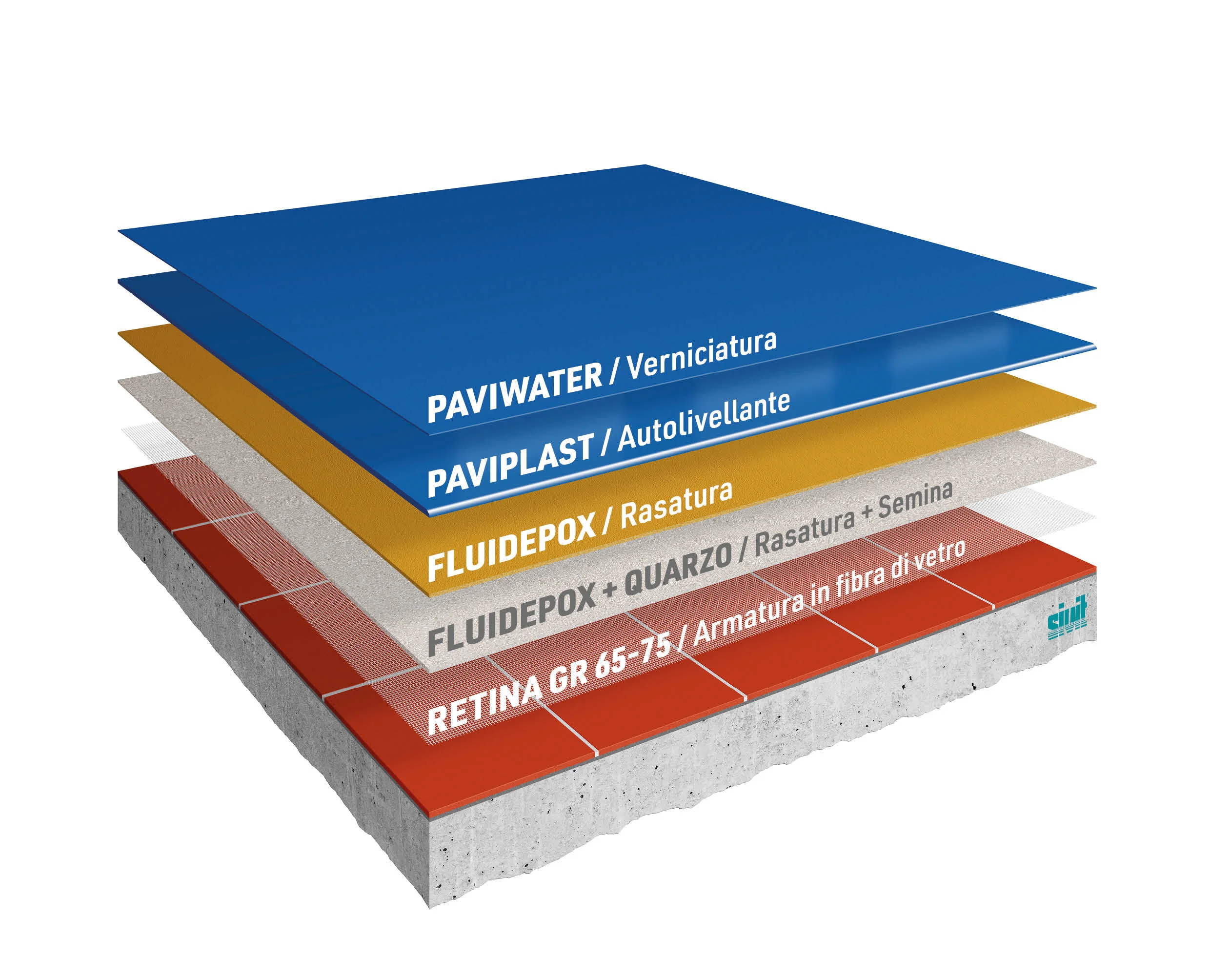

Valutare il tipo di preparazione meccanica più conveniente (levigatura, pallinatura o fresatura) e quindi applicare una ripresa di FLUIDEPOX. Eventuali buchi e lievi anomalie, possono essere riparati con PAVIRAPID.

Pavimenti piastrellati vanno levigati o pallinati fino a superficie completamente opacizzata, quindi applicare una o più riprese di ECOFONDO PLUS FIBRATO o FLUIDEPOX (vedere ciclo applicativo specifico o contattare l'Assistenza Tecnica Sivit).

Rivestimenti in resina già esistenti vanno abrasivati o pallinati, eliminando quindi i residui di polvere.

Non applicare PAVIPLAST su supporti umidi o sottoposti a umidità di risalita capillare (nel caso, contattare il Servizio Tecnico Sivit). L'umidità del supporto non deve superare il 4%.

Applicazione

Al momento dell’applicazione unire i due componenti in un unico recipiente e miscelare con cura per 2 minuti, utilizzando adeguata attrezzatura (trapano ad elica).

Utilizzare rapidamente l’intero contenuto del recipiente. Nello svuotare il contenitore evitare di raschiare i bordi e il fondo, in quanto potrebbe esserci del prodotto non perfettamente amalgamato.

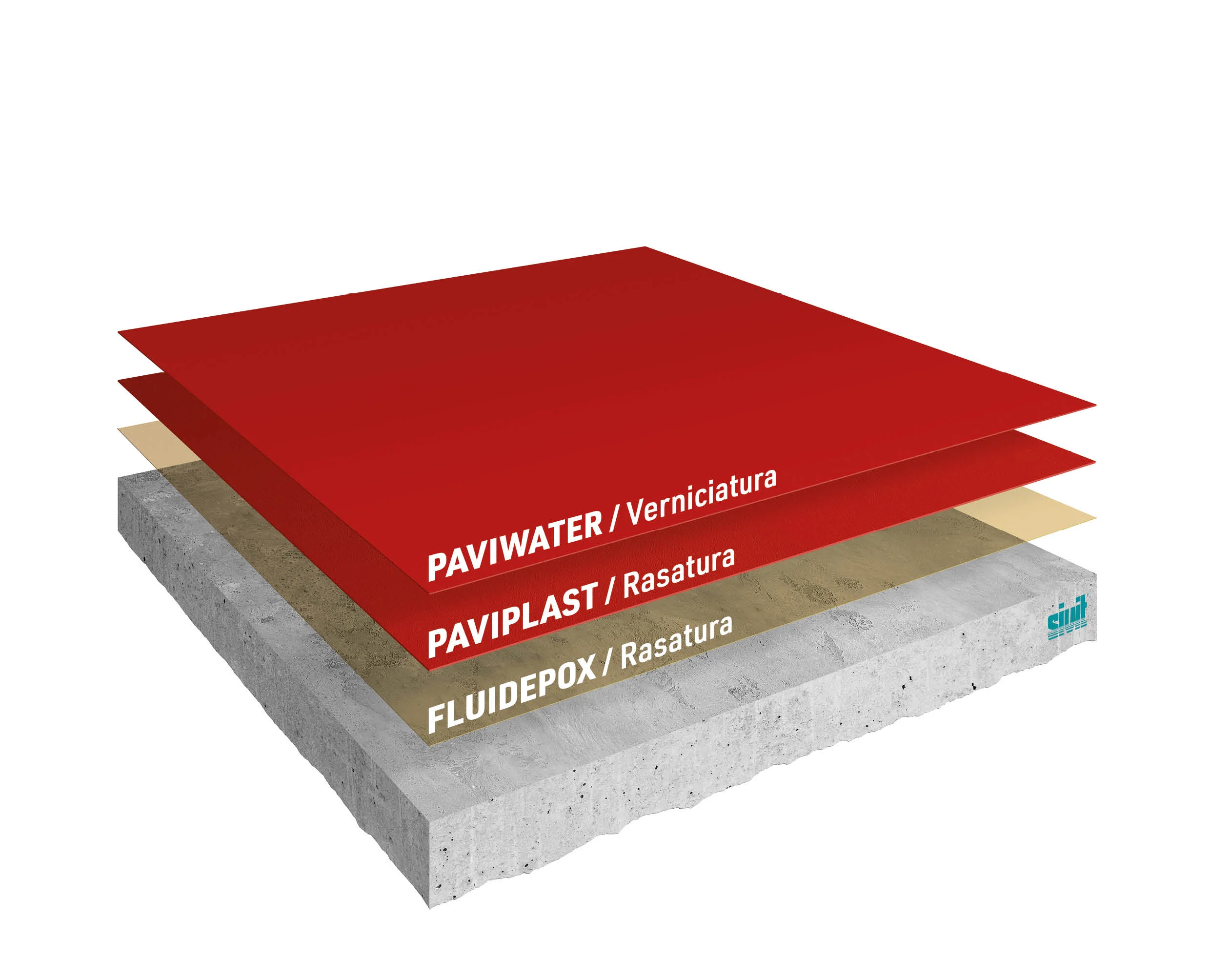

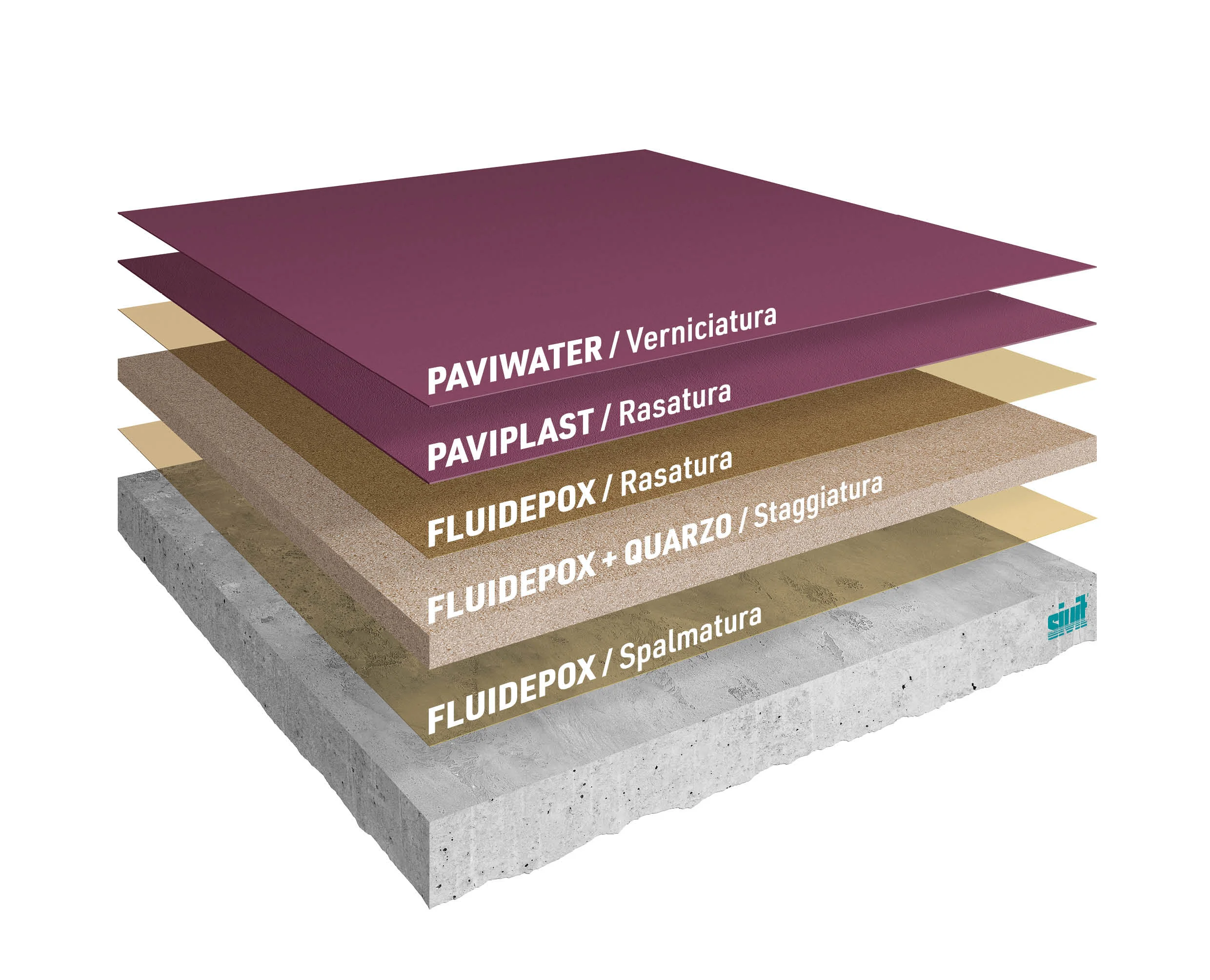

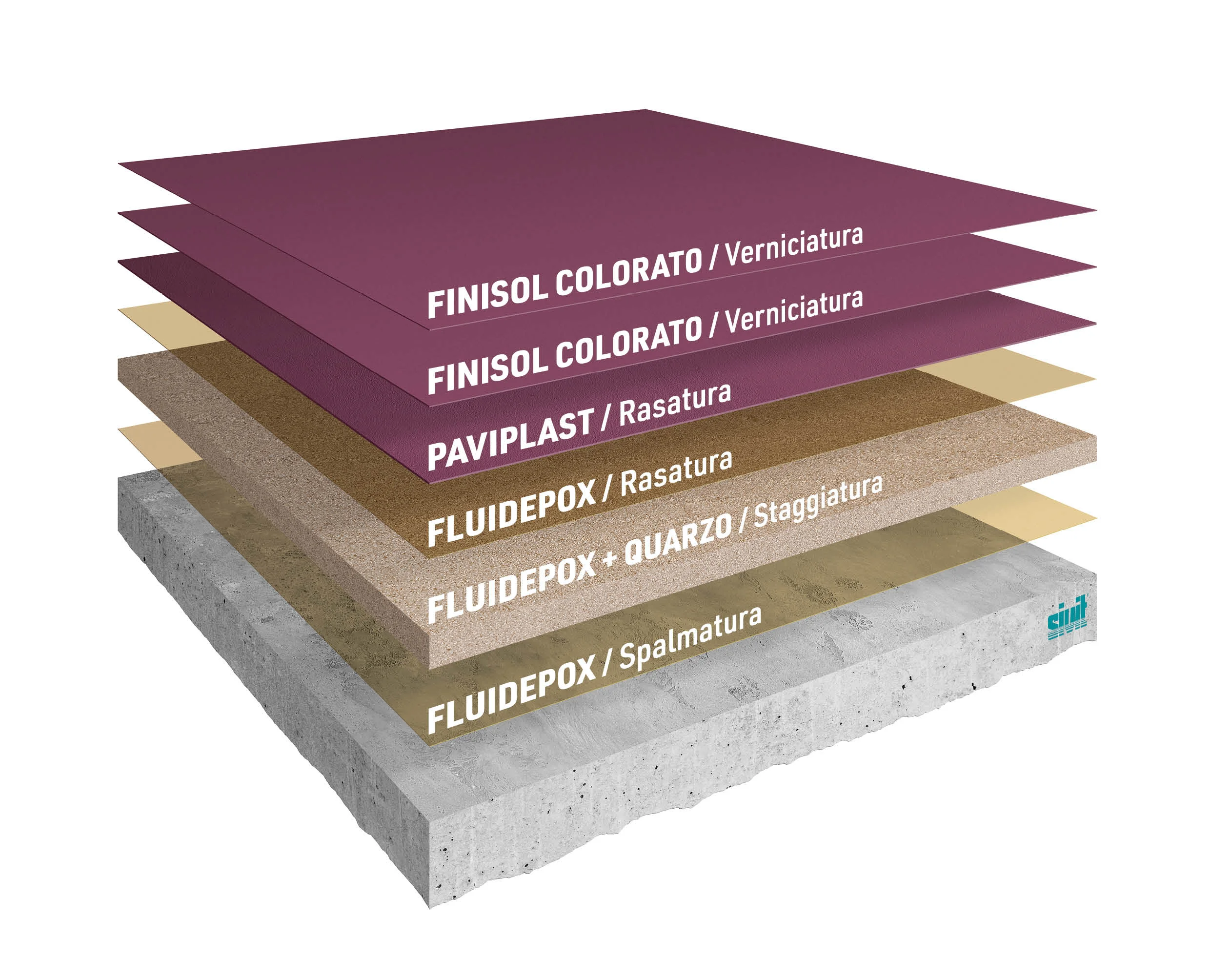

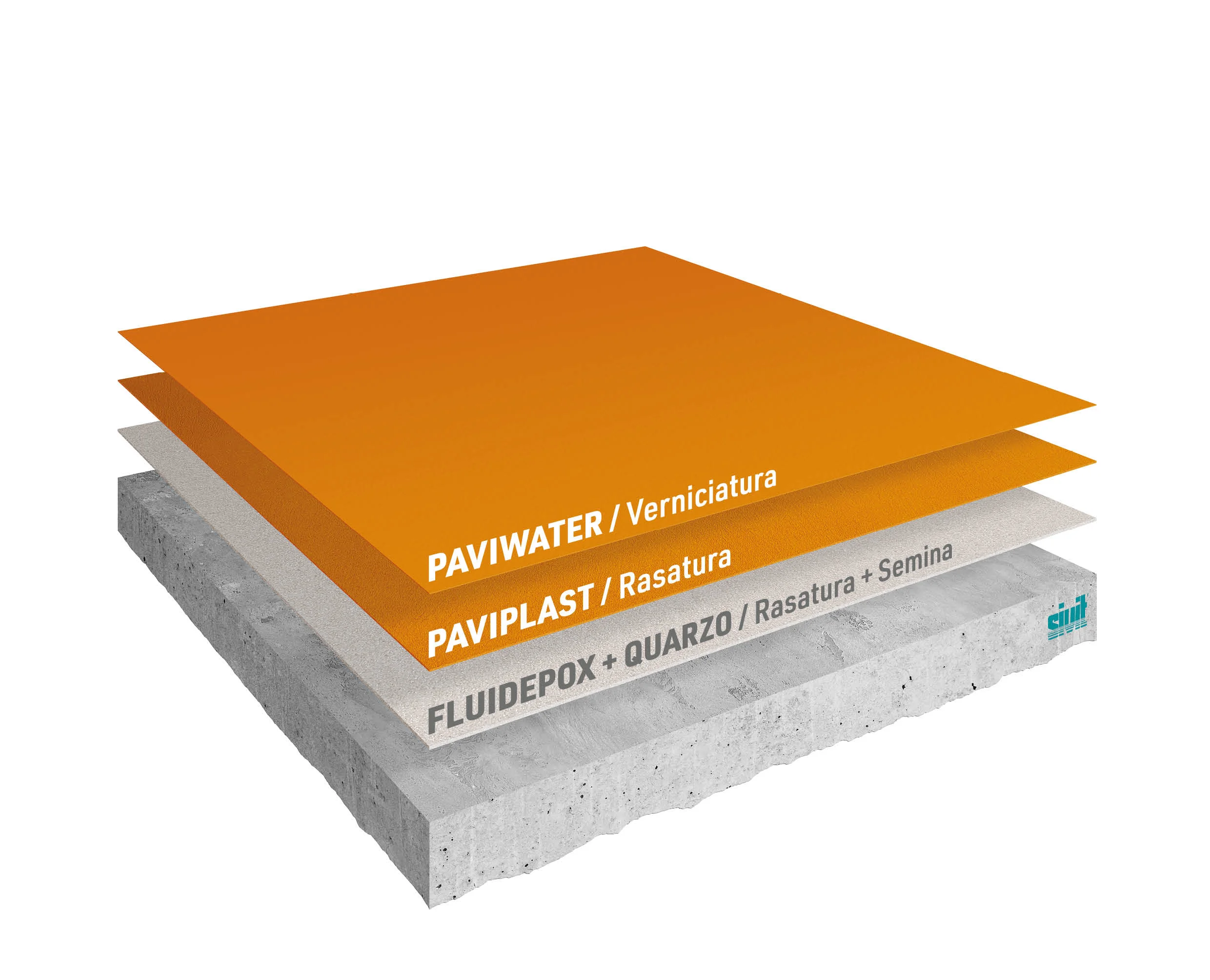

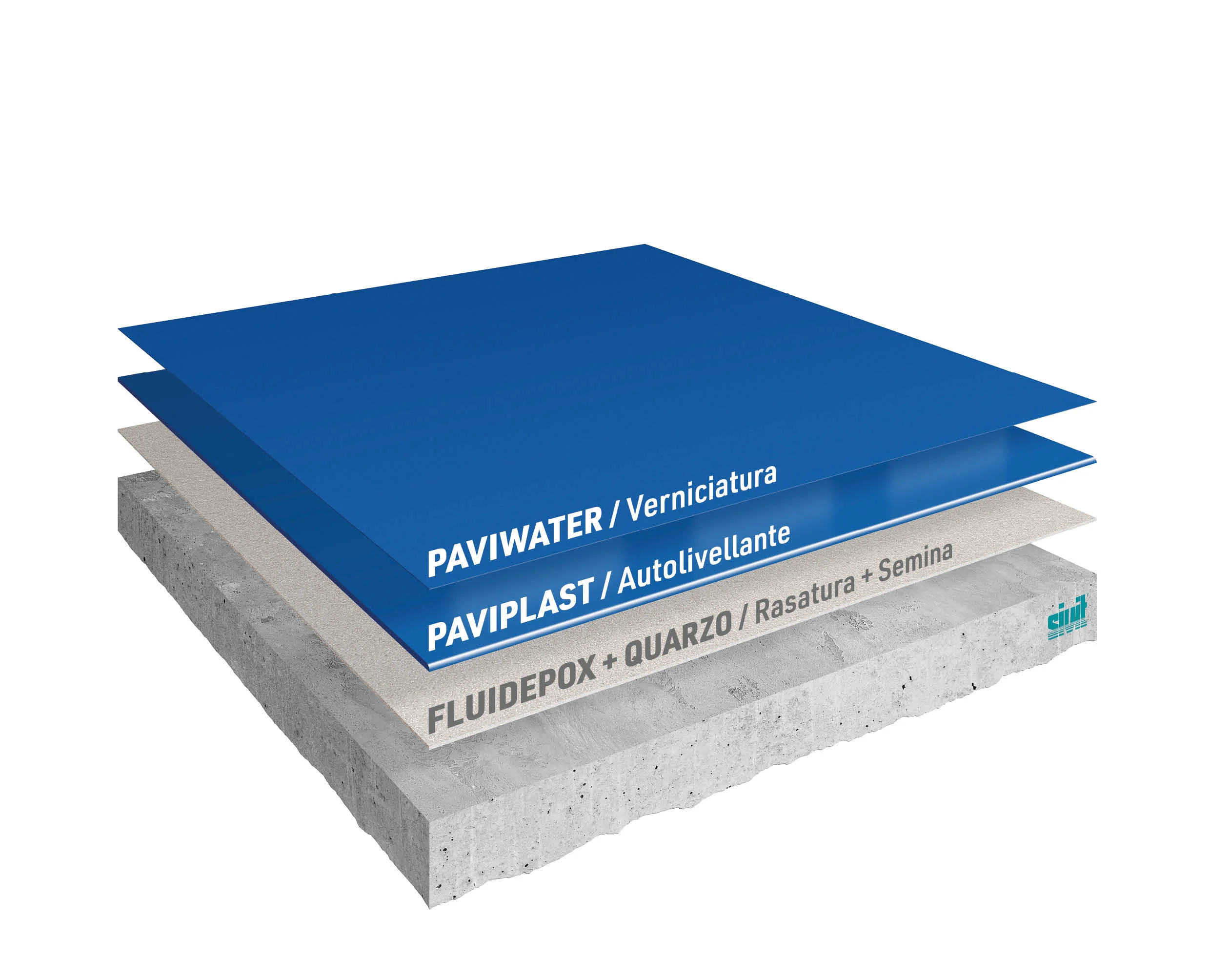

Utilizzo nei Cicli Autolivellanti

Dopo avere miscelato i due componenti, aggiungere QUARZO B0 (0,8 kg per 1 kg di A+B) e rimescolare.

La modalità applicativa principale del PAVIPLAST è come “autolivellante”. In questo caso occorre stendere il prodotto con cazzuola dentata da 5 mm.

Entro 5 minuti passare il rullo frangibolle con movimenti lenti e regolari per uniformare la superficie. Il consumo per 2,5 mm di spessore e di 2,2 kg/m2 di (A+B) e di 1,76 kg/m2 di QUARZO B0.

Utilizzo nei Cicli di Rasatura e Multistrato

Dopo avere miscelato i due componenti, aggiungere QUARZO B0 e rimescolare . La quantità di inerte da aggiungere è la seguente:

- 0,8 kg per 1 kg di A+B, per i Cicli di Rasatura

- 0,5 kg per 1 kg di A+B, per i Cicli Multistrato

Stendere il prodotto con movimenti a ventaglio, curando di non lasciare materiale in eccesso ed uniformando a fresco con rullo. Il consumo per ogni ripresa è:

- di 0,35 kg/m2 di (A+B) e di 0,28 kg/m2 di QUARZO B0, per i Cicli di Rasatura

- di 0,7 kg/m2 di (A+B) e di 0,35 kg/m2 di QUARZO B0, per i Cicli Multistrato

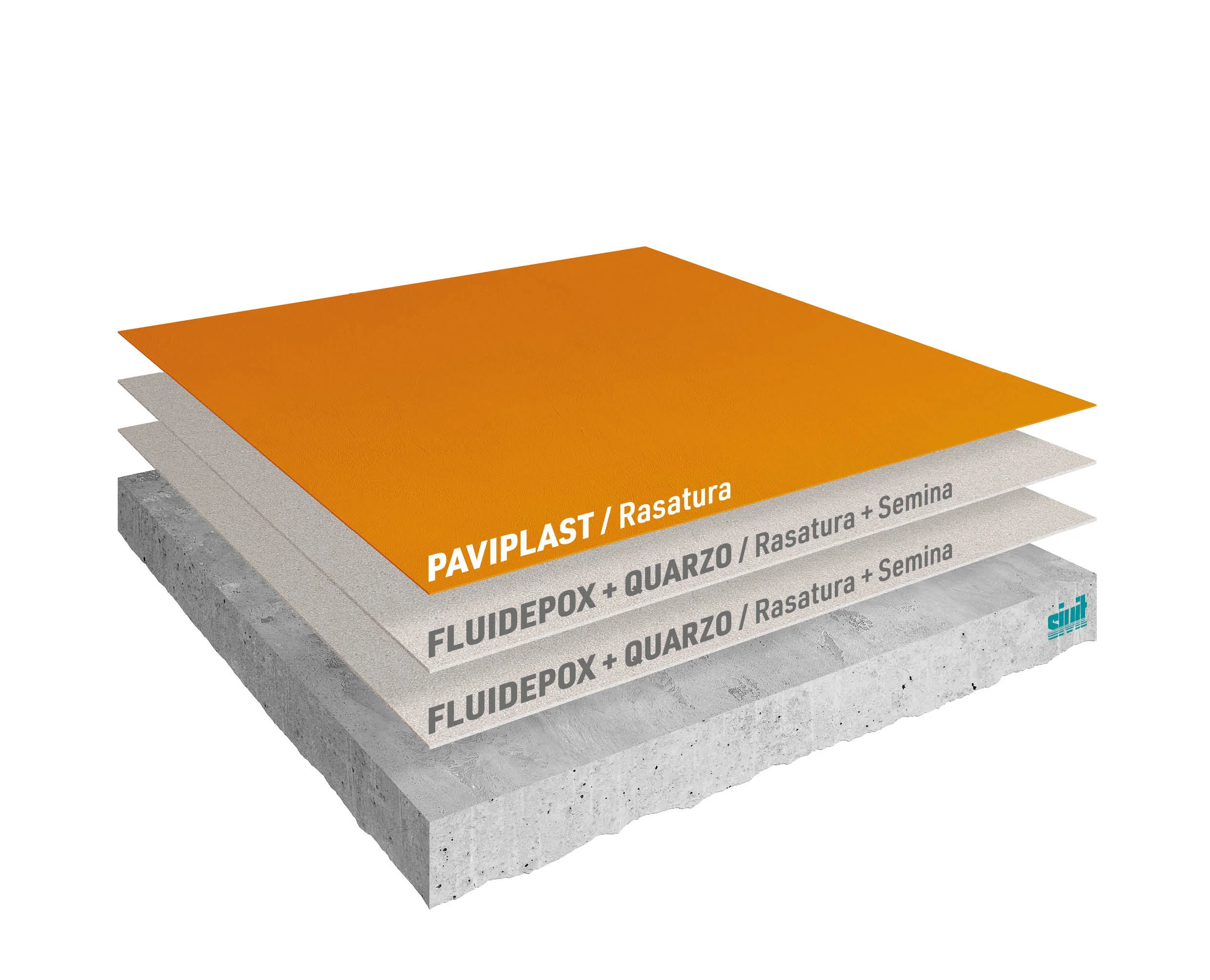

Utilizzo nei Cicli di Verniciatura

Dopo avere miscelato i due componenti, verificare la viscosità del sistema, che varia molto con la temperatura.

Per ottenere superfici antiscivolo:

- applicare una prima ripresa di PAVIPLAST (per un consumo di 0,4 kg/m2 ) e quindi seminare uniformemente 1 kg/m2 di QUARZO B3

- dopo 12-36 ore, applicare una seconda ripresa di PAVIPLAST (per un consumo di 0,5 kg/m2 )

Per verniciature ad alto spessore:

- applicare PAVIPLAST in due riprese, per un consumo complessivo di circa 0,6 kg/m2

In caso di realizzazione di verniciatura, PAVIPLAST può essere diluito con Solvente UNI, per un massimo del 3% in peso (A+B).

Avvertenze

I rivestimenti di PAVIPLAST esposti alla luce solare possono subire sbiadimenti o variazioni di colore con viraggio verso il giallo: questo fatto non pregiudica in alcun modo le prestazioni del rivestimento. Tra diversi lotti di produzione del medesimo colore ci possono essere leggere differenze: quando è possibile utilizzare materiale proveniente dal medesimo lotto.

Per applicazioni a bassa temperatura si può scaldare il materiale a 25°C per facilitarne l’applicazione e la catalisi (diminuzione viscosità).

Prodotto ad uso professionale, l’acquirente si impegna a seguire tassativamente le avvertenze sopra riportate nell’applicazione del prodotto acquistato e le indicazioni della scheda di sicurezza.

Specifiche tecniche

| DATI PRODOTTO | |

|---|---|

| Colore | Come da listino o a richiesta secondo cartella RAL (per lotti minimi di 200kg) |

| Consumo: a rasare come autolivellante |

0,35 kg/m2 di (A+B) + di 0,28 kg/m2 di Quarzo 2,2 kg/m2 di (A+B) + 1,76 kg/m2 di QUARZO B0 (per 2,5 mm di spessore) |

| Peso specifico (a 25°C): miscela (A+B) miscela (A+B) caricata |

1,25 +/- 0,05 g/ml 1,60 +/- 0,10 g/ml (con 80% di QUARZO B0) |

| Viscosità (a 25°C): miscela (A+B) miscela (A+B) caricata |

800 +/- 170 mPa•s (spindle 2, rpm 30) 1.300 +/- 700 mPa•s (con 80% di QUARZO B0, spindle 2, rpm 6) |

| Residuo secco (A+B) | > 98% |

| VOC pronto uso (D.lgs 161/06) | < 200 g/l Cat.A/j. Pittura bicomponente ad alte prestazioni (BS) |

| Punto di infiammabilità | > 100°C |

| Solvente per la pulizia attrezzi | Solvente UNI |

| Magazzinaggio | 12 mesi, conservare in luogo asciutto ad una temperatura compresa tra i 5°C ed i 35°C |

| DATI APPLICAZIONE E TEMPI | |

|---|---|

| Rapporto di miscela (in peso) | Versione già in tinta: A=100, B=32 Versione NP: A=95, pasta=5, B=32 |

| Pot-life (50% U.R.) | a 15°C > 40 min a 25°C 30 min |

| Secco al tatto (50% U.R.) | a 15°C 12-16 ore a 25°C 5-7 ore |

| Pedonabile (50% U.R.) | a 25°C 12 ore |

| Ricopertura (50% U.R.) | a 25°C da 12 a 36 ore |

| Trafficabile (50% U.R. | a 25°C 36 ore |

| Indurimento in profondità (50% U.R.) | a 25°C 7 giorni |

| Condizioni ambientali d’uso | Temperature comprese tra i +15°C e i +35°C, U.R. < 50% e umidità del supporto < 4% (*) |

| Manutenzione rivestimento | Per le operazioni di pulizia utilizzare detergenti neutri |

| DATI TECNICI PRESTAZIONALI | |

|---|---|

| Aspetto | Lucido e planare |

| Gloss(60°) | 95 (*) |

| Resistenza all’abrasione norma UNI 8298-9 | 70-80 mg (TABER Mola CS-17-1000 giri - 1000 g di peso) |

| Resistenza a compressione (UNI 4279) | 60 N/mm2 |

| Modulo a compressione | 1,5 GPa |

| Resistenza a flessione (UNI 7219) | 59 N/mm2 |

| Resistenza a trazione (ASTM D 638) | 40 N/mm2 |

| Durezza (ASTM D 2240) | 78 Shore D |

| Adesione (DIN ISO 4624) | >1,5 N/mm2 |

| Coefficiente dilatazione termica lineare | 20 x10-6°C-1 |

| Resistenze chimiche | Contattare il Servizio Tecnico Sivit per informazioni dettagliate |

| Marcatura CE (reg. n. 305/2011) | Conforme a EN13813:2004. Materiali per massetti a base di resina sintetica per l'utilizzo all'interno di edifici. |

| Resistenza all’usura BCA (EN 13892-4) | AR 0,5 |

| Resistenza all’urto (EN 6272-1) | IR 10 |

| Forza di aderenza (EN 12892-8) | B2 |

| (*) PAVIPLAST applicato a temperature del supporto inferiori ai 15°C potrebbe macchiarsi a contatto con l’acqua, o con preparati a base acquosa, e formare macchie biancastre. Tale difetto di resistenza chimica è causato da una reticolazione incompleta. Pertanto, PAVIPLAST va applicato ad una temperatura del supporto non inferiore a 15°C e di almeno 3°C superiore alla temperatura di condensa. | |