FLUIDEPOX® FLEX A+B

Formulato epossidico trasparente elastico

Formulato dotato di buona elasticità, può essere usato come primer per consolidare supporti in calcestruzzo danneggiati o per realizzare rivestimenti in resina per parcheggi.

Se usato come impregnante per fibra di vetro, consente di realizzare rivestimenti in vetroresina.

Tipologia: Leganti e Primer Epossidici

Descrizione

Prodotto bicomponente a base di resine epossi-poliuretaniche e indurenti amminici.

Indicato come consolidante per supporti in cls, mantiene nel tempo una flessibilità permanente.

Utilizzi

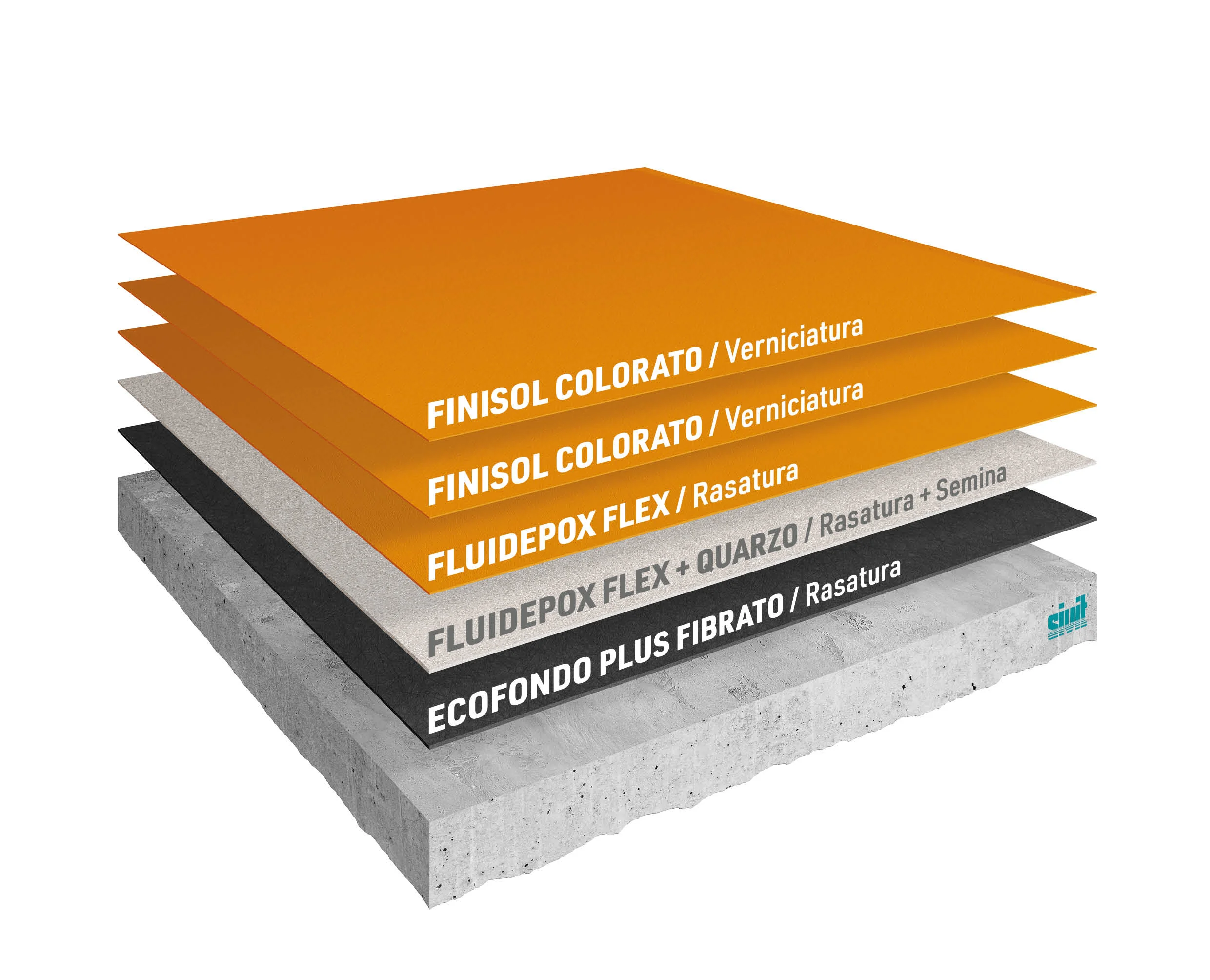

Primer per supporti cementizi.

Intermedio in cicli applicativi flessibili.

Impregnazioni di fibra di vetro per realizzare rivestimenti in vetroresin

Supporto

Il sottofondo deve possedere una resistenza minima alla compressione di 25 N/mm2 e a trazione di 1,5 N/mm2

Preparazione del supporto

Operando su fondi in cls occorre verificare che non vi siano risalite di umidità. Se il cls è di nuova costruzione si dovrà attendere la maturazione completa.

La superficie si dovrà presentare solida, assorbente ed esente da presenza di oli, tensioattivi, acqua, polvere. Eventuali parti inconsistenti dovranno essere rimosse.

Le pavimentazioni vanno trattate meccanicamente, mediante levigatura, pallinatura o fresatura.

Applicazione

Al momento dell’applicazione unire la parte A e la parte B in un unico contenitore e miscelare con cura per 2 minuti utilizzando adeguata attrezzatura (trapano ad elica).

Utilizzare rapidamente l’intero contenuto del recipiente.

Nello svuotare il contenitore evitare di raschiare i bordi e il fondo, in quanto potrebbe esserci del prodotto non perfettamente amalgamato.

Applicare con spatola americana, caricato con 50% di QUARZO B0 o B1, per rasature semplici o rivestimenti multistrato.

Avvertenze

Per applicazioni a bassa temperatura si può scaldare il materiale a 25°C per facilitare l’applicazione e la catalisi (diminuzione viscosità).

Prodotto ad uso professionale, l’acquirente si impegna a seguire tassativamente le avvertenze sopra riportate nell’applicazione del prodotto acquistato e le indicazioni della scheda di sicurezza.

Specifiche tecniche

| DATI PRODOTTO | |

|---|---|

| Colore | Trasparente |

| Consumo (a rasare) | 0,350 kg/m2 di (A+B) e 0,175 kg/m2 di QUARZO B0 |

| Peso specifico (a 25°C): miscela (A+B) miscela (A+B) e 50% di QUARZO B0 |

1,10 +/- 0,05 g/ml 1,50 +/- 0,10 g/ml |

| Viscosità (a 25°C): miscela (A+B) miscela (A+B) diluita al 5% con SOLVENTE UNI |

2.700 mPa•s (spindle 2, rpm 10) 1.700 mPa•s (spindle 2, rpm 12) |

| Punto di infiammabilità | > 100°C |

| Solvente per la pulizia attrezzi | Solvente UNI |

| Magazzinaggio | 12 mesi, conservare in luogo asciutto ad una temperatura compresa tra i 5°C ed i 35°C |

| DATI APPLICAZIONE E TEMPI | |

|---|---|

| Rapporto di miscela | in peso: A=100, B=28,2 |

| Pot-life (50% U.R.) | a 10°C > 80-100 min a 25°C 50-60 min a 30°C > 30-40 min |

| Secco al tatto (50% U.R.) | a 10°C 36-40 ore a 25°C 18-20 ore a 30°C 12-14 ore |

| Pedonabile (50% U.R.) | a 25°C 24 ore |

| Ricopertura (50% U.R.) | a 25°C da 24 a 48 ore |

| Trafficabile (50% U.R.) | a 25°C 72 ore |

| Indurimento in profondità (50% U.R.) | a 25°C 7 giorni |

| Condizioni ambientali d’uso | Temperature comprese tra i +10°C e i +30°C, U.R. < 60% e umidità del supporto < 4% (*) |

| DATI TECNICI PRESTAZIONALI | |

|---|---|

| Resistenza a trazione (UNI EN ISO 527) | a -10°C 2,98 Mpa a +10°C 1,97 MPa00 |

| Allungamento a rottura (UNI EN ISO 527) | a -10°C 183 % a +10°C 166 % |

| Modulo di elasticità a trazione (UNI EN 527) | a -10°C 14 MPa a +10°C 9 MPa |

| Crack bridging - Metodo A statico (UNI EN 1062-7) | a +10°C A2 > 250 µm |

| (*) FLUIDEPOX FLEX va applicato ad una temperatura del supporto di almeno 3°C superiore alla temperatura di condensa. | |