FLUIDEPOX® ANTIFIAMMA A+B+C

Formulato epossidico antifiamma

Primer per la realizzazione di superfici antifiamma, grazie al suo potere penetrante è in grado di consolidare supporti in calcestruzzo.

Può essere steso sul calcestruzzo per migliorare l’adesione dei rivestimenti in resina, essere utilizzato come impregnante per mat in fibra di vetro nella creazione di rivestimenti in vetroresina, diventare un legante per sistemi multistrato.

Fluidepox Antifiamma è reattivo anche alle basse temperature.

Tipologia: Leganti e Primer Epossidici

Descrizione

Prodotto tricomponente a base di resine epossidiche, usate in combinazione con indurenti amminici cicloalifatici e carica apirogenica.

Presenta buon potere penetrante e consolidante per supporti in calcestruzzo.

La particolare struttura chimica dell’indurente amminico garantisce una buona reattività del sistema anche alle basse temperature.

Utilizzi

Primer per cls ideale per favorire l’adesione dei rivestimenti in resina. Impregnazioni di mat di vetro per realizzare rivestimenti in vetroresina.

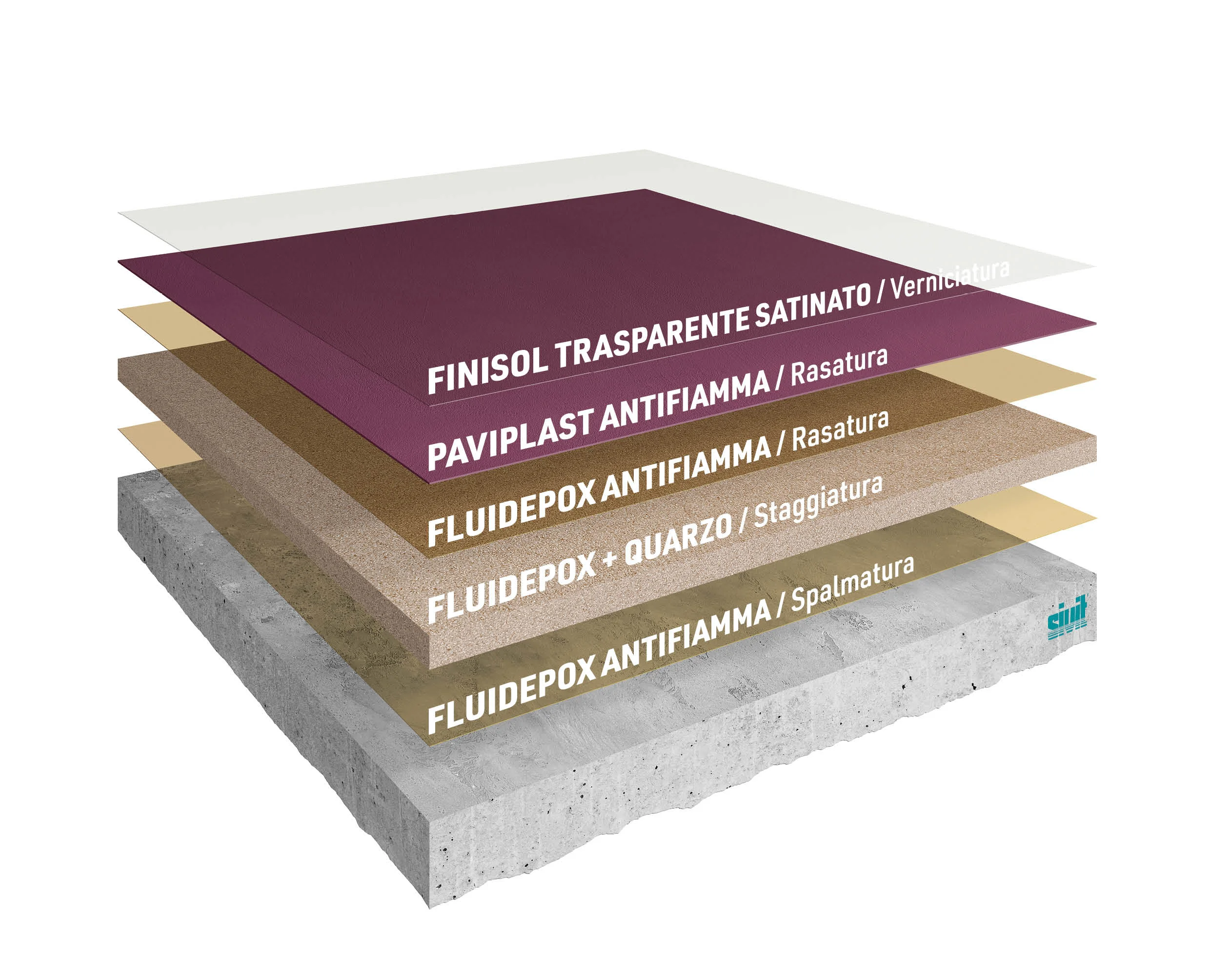

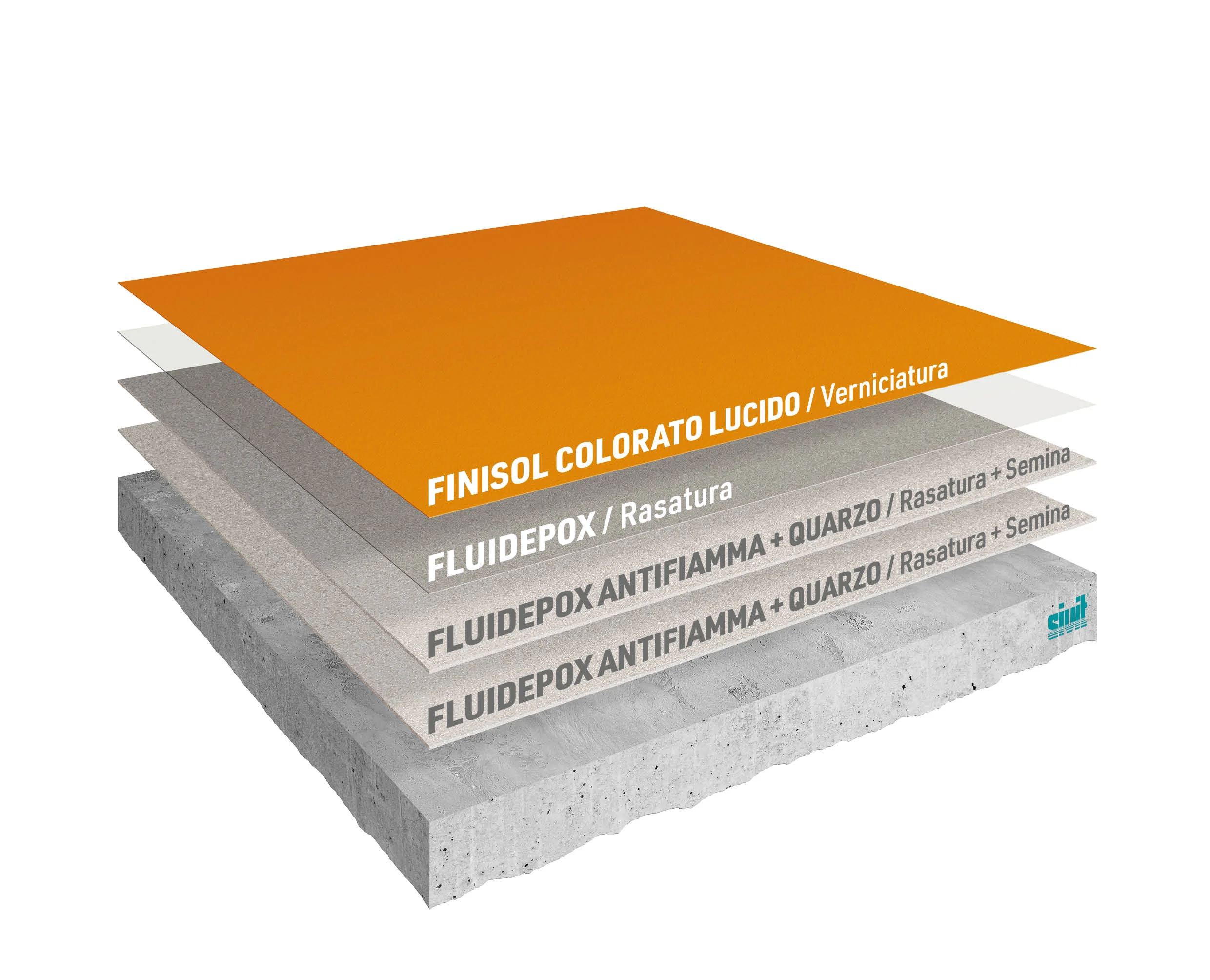

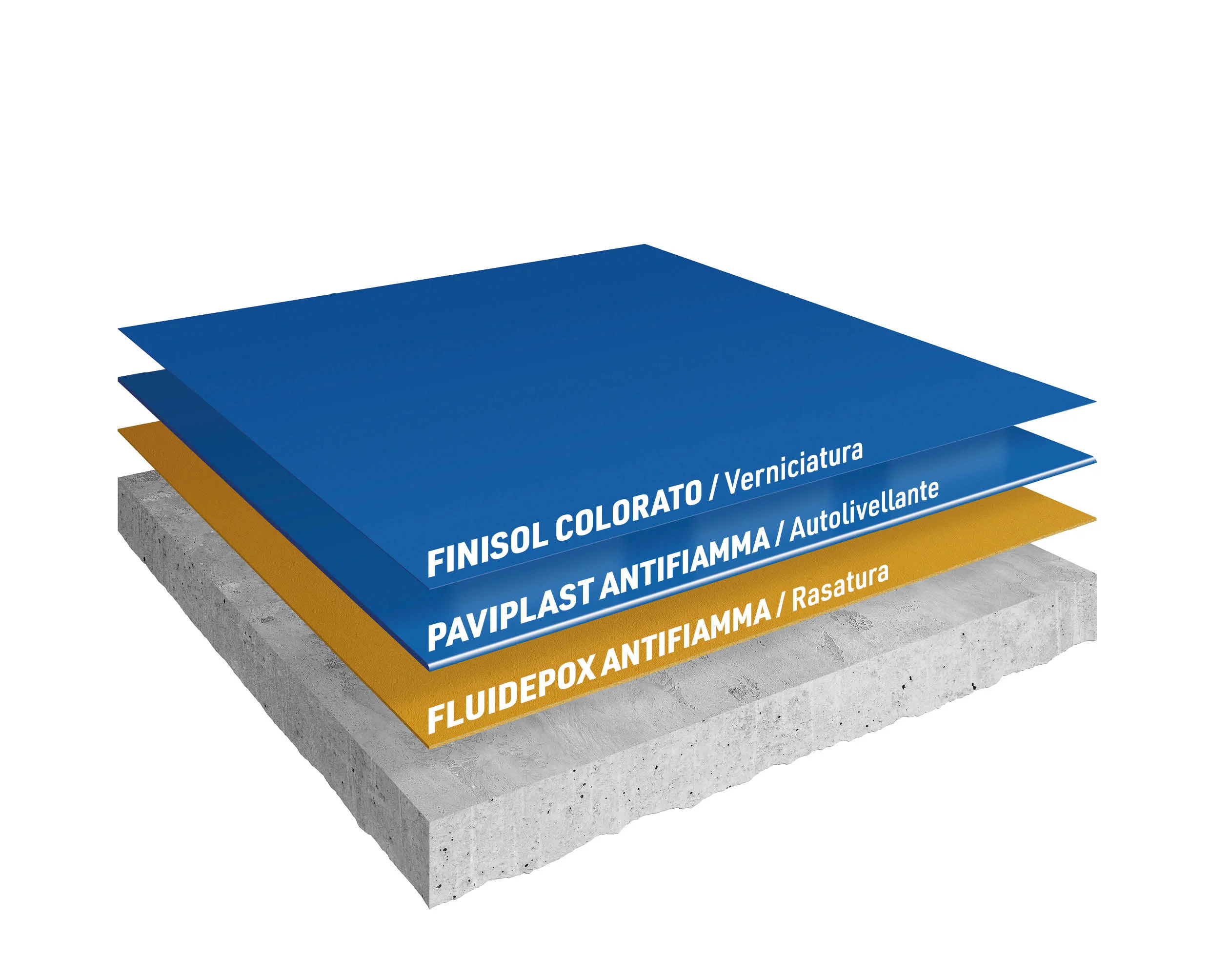

Legante per sistemi multistrato. Rivestimenti in resina con classe di reazione al fuoco BFL-S1

Supporto

Il sottofondo deve possedere una resistenza minima alla compressione di 25 N/mm2 e a trazione di 1,5 N/mm2.

Preparazione del supporto

Operando su fondi in cls. occorre verificare che non vi siano risalite di umidità. Se il cls. è di nuova costruzione si dovrà attendere la maturazione completa.

La superficie si dovrà presentare solida, assorbente ed esente da presenza di oli, tensioattivi, acqua , polvere. Eventuali parti inconsistenti dovranno essere rimosse.

Le pavimentazioni vanno trattate meccanicamente, mediante abrasivazione, pallinatura o fresatura.

Applicazione

Al momento dell’applicazione unire la parte A e la parte B in un unico contenitore e miscelare con cura per 2 minuti mediante agitatore meccanico.

Dopo avere ottenuto una miscela omogenea, aggiungere la carica apirogenica e miscelare con cura con agitatore meccanico per due minuti.

FLUIDEPOX ANTIFIAMMA può essere applicato in diversi modi:

- a rasare con cazzuola o racla, puro o caricato con QUARZO B0

- su supporti dove è ipotizzabile una risalita di umidità occorre distribuire su FLUIDEPOX ANTIFIAMMA appena applicato del quarzo a rifiuto; procedere quindi con rivestimenti traspiranti

I consumi variano sensibilmente secondo le applicazioni e lo stato del sottofondo: consultare i nostri cicli per avere un riferimento più preciso.

Avvertenze

Per applicazioni a bassa temperatura si può scaldare il materiale a 25°C per facilitare l’applicazione e la catalisi (diminuzione viscosità).

Prodotto ad uso professionale, l’acquirente si impegna a seguire tassativamente le avvertenze sopra riportate nell’applicazione del prodotto acquistato e le indicazioni della scheda di sicurezza.

Specifiche tecniche

| DATI PRODOTTO | |

|---|---|

| Colore | Giallino |

| Peso specifico (a 25°C): miscela (A+B+C) |

1,30 +/- 0,05 g/ml |

| Viscosità (a 25°C): miscela (A+B+C) |

1.000 +/- 200 mPascal (spindle 2 rpm 60) |

| Punto di infiammabilità | > 100°C |

| Solvente per la pulizia attrezzi | Solvente UNI |

| Magazzinaggio | 12 mesi, conservare in luogo asciutto ad una temperatura compresa tra i 5°C ed i 35°C |

| DATI APPLICAZIONE E TEMPI | |

|---|---|

| Rapporto di miscela | in peso: A=100, B=50, C=75 |

| Pot-life (50% U.R.) | a 10°C > 60 min a 25°C 30 min a 30°C > 20 min |

| Secco al tatto (50% U.R.) | a 10°C 12-16 ore a 25°C 5-7 ore a 30°C 2-3 ore |

| Pedonabile (50% U.R.) | a 25°C 12 ore |

| Ricopertura (50% U.R.) | a 25°C da 12 a 36 ore |

| Trafficabile (50% U.R.) | a 25°C 36 ore |

| Indurimento in profondità (50% U.R.) | a 25°C 7 giorni |

| Condizioni ambientali d’uso | Temperature comprese tra i +10°C e i +30°C, U.R. < 60% e umidità del supporto < 4 (*) |

| DATI TECNICI PRESTAZIONALI | |

|---|---|

| Resistenza a compressione (UNI 4279) | 58 N/mm2 |

| Resistenza a flessione (UNI 7219) | 50 N/mm2 |

| Resistenza a trazione (ASTM D 638) | 38 N/mm2 |

| Durezza (ASTM D 2240) | 78 Shore D |

| Resistenze chimiche | Buona resistenza nei confronti di vari aggressivi (consultare il nostro Servizio Tecnico) |

| (*) FLUIDEPOX ANTIFIAMMA va applicato ad una temperatura del supporto non inferiore a 15°C e di almeno 3°C superiore alla temperatura di condensa | |