PAVIRESISTANT TIXO A+B

Formulato epossidico per rivestimenti chimico resistenti

Utilizzato per realizzare protezioni impermeabili per canaline e vasche di contenimento, è resistente al contatto con aggressivi chimici come acidi, basi e solventi, soprattutto acetato di etile.

Tipologia: Rivestimenti Anticorrosivi

Descrizione

Prodotto bicomponente a base di resina epossidiche usate in combinazione con indurenti amminici cicloalifatici.

Formulato al 90% in peso di residuo secco, utilizzato per realizzare rivestimenti resistenti al contatto con aggressivi chimici (acidi, basi, solventi in particolare acetato di etile).

Utilizzi

Protezione impermeabile di canaline e vasche di contenimento.

Supporto

Il sottofondo deve possedere una resistenza minima alla compressione di 25 N/mm2 e a trazione di 1,5 N/mm2

Preparazione del supporto

Fondi in cls dovranno essere solidi, asciutti (stagionati se di nuova costruzione), livellati, assorbenti, non inquinati da oli, detergenti, polveri od altre sostanze.

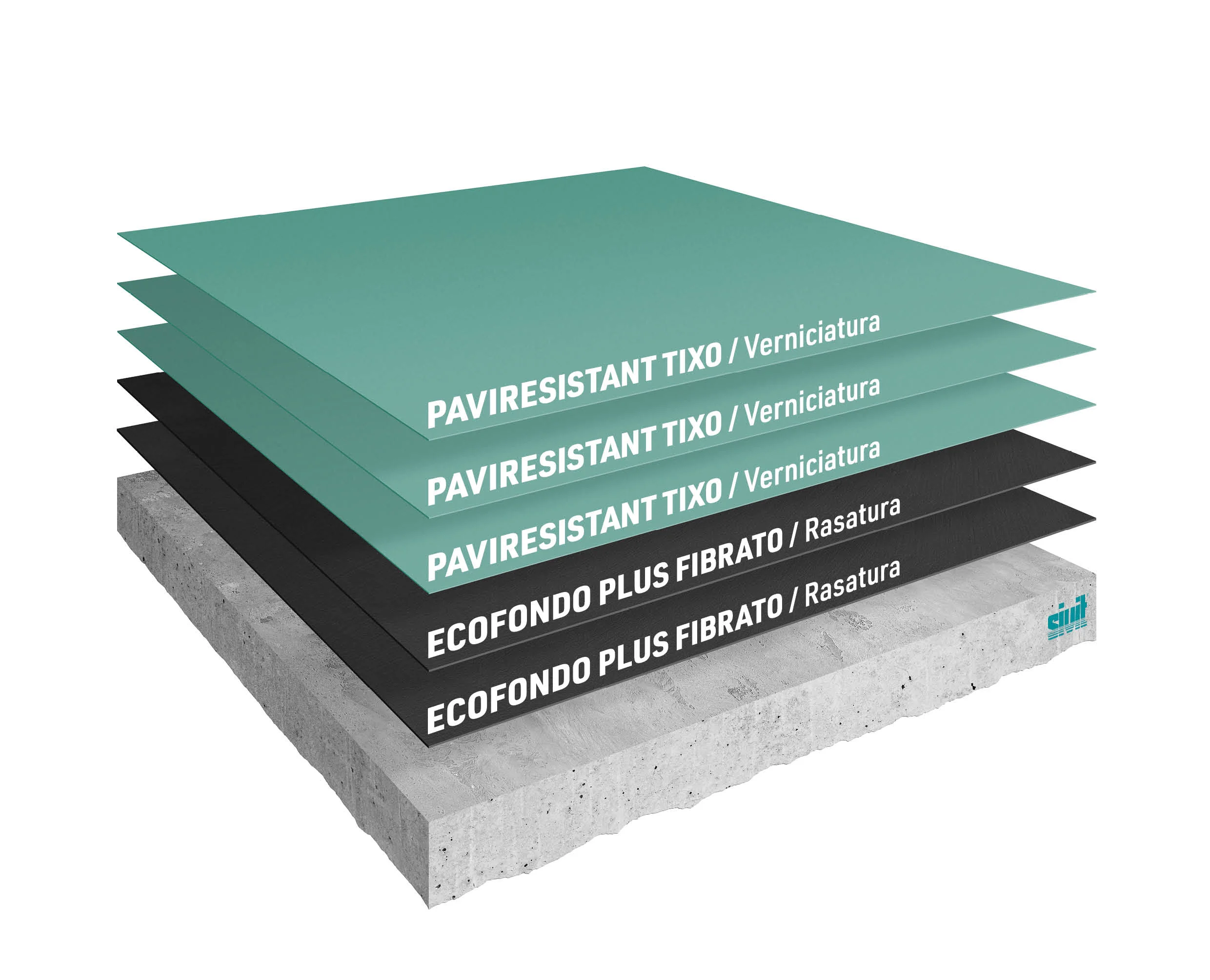

Valutare il tipo di preparazione meccanica più conveniente (sabbiatura, idrolavaggio) e quindi applicare su supporto regolarizzato una ripresa di ECOFONDO.

Applicazione

Al momento dell’applicazione unire i due componenti in un unico recipiente e miscelare con cura con adeguata attrezzatura.

Utilizzare rapidamente l’intero contenuto. Nello svuotare il contenitore evitare di raschiare i bordi ed il fondo, in quanto potrebbe esserci del prodotto non perfettamente amalgamato. Applicare il prodotto tramite rullo o pennello con un consumo di 300-600 gr/m2

Avvertenze

I rivestimenti di PAVIRESISTANT TIXO esposti alla luce solare possono subire sbiadimenti o variazioni di colore con viraggio verso il giallo; questo fatto non pregiudica in alcun modo le prestazioni del rivestimento.

Tra diversi lotti produttivi dello stesso colore ci possono essere leggere differenze: quando possibile utilizzare materiale proveniente dallo stesso lotto di produzione.

Per applicazioni a bassa temperatura si può scaldare il materiale a 25°C per facilitarne l’applicazione e la catalisi (diminuzione viscosità). Tonalità sul giallo, arancione o alcuni rossi possono richiedere più riprese per ottenere un buon effetto coprente.

Prodotto ad uso professionale, l’acquirente si impegna a seguire tassativamente le avvertenze sopra riportate nell’applicazione del prodotto acquistato e le indicazioni della scheda di sicurezza.

Specifiche tecniche

| DATI PRODOTTO | |

|---|---|

| Colore | Colore RAL 7038 o a richiesta, per lotti minimi di 200 kg |

| Peso specifico (a 25°C): miscela (A+B) |

1,20 +/- 0,05 g/ml |

| Viscosità (a 25°C): miscela (A+B) |

5.000 +/- 1.000 mPa (spindle 2, rpm 6) |

| Punto di infiammabilità | > 100 °C |

| Solvente per la pulizia attrezzi | Solvente UNI |

| Magazzinaggio | 12 mesi, conservare in luogo asciutto ad una temperatura compresa tra i 5°C ed i 35°C |

| DATI APPLICAZIONE E TEMPI | |

|---|---|

| Rapporto di miscela | in peso: A=100, B=28,5 |

| Pot-life (50% U.R.) | a 15°C > 6 ore a 25°C 17 min a 30°C > 10 min |

| Secco al tatto (50% U.R.) | a 15°C 10-12 ore a 25°C 2-3 ore (per bassi spessori) a 30°C 1-2 ore |

| Pedonabile (50% U.R.) | a 25°C 10 ore |

| Ricopertura (50% U.R.) | a 25°C da 6 a 24 ore |

| Trafficabile (50% U.R.) | a 25°C 20 ore |

| Condizioni ambientali d’uso | Temperature comprese tra i +15°C e i +30°C, U.R. < 50% e umidità del supporto < 4 (*) |

| Manutenzione rivestimento | Per le operazioni di pulizia utilizzare detergenti neutri |

| DATI TECNICI PRESTAZIONALI | |

|---|---|

| Resistenza a compressione (UNI 4279) | 60 N/mm2 |

| Resistenza a flessione (UNI 7219) | 45 N/mm2 |

| Resistenza a trazione (ASTM D 638) | 30 N/mm2 |

| Durezza (ASTM D 2240) | 80 Shore D |

| Resistenze chimiche | Ottima resistenza nei confronti di vari aggressivi (consultare il nostro Servizio Tecnico) |

| (*) PAVIRESISTANT TIXO applicato a temperature del supporto inferiori ai 15°C potrebbe macchiarsi a contatto con l’acqua o con preparati a base acquosa e formare macchie biancastre. Tale difetto di resistenza chimica è causato da una reticolazione incompleta. Pertanto, PAVIRESISTANT TIXO va applicato ad una temperatura del supporto non inferiore a 15°C e di almeno 3°C superiore alla temperatura di condensa. | |