PAVIPLAST® VASCHE TIX A+B

Formulato epossidico tissotropico per rivestimenti di opere di ingegneria idraulica

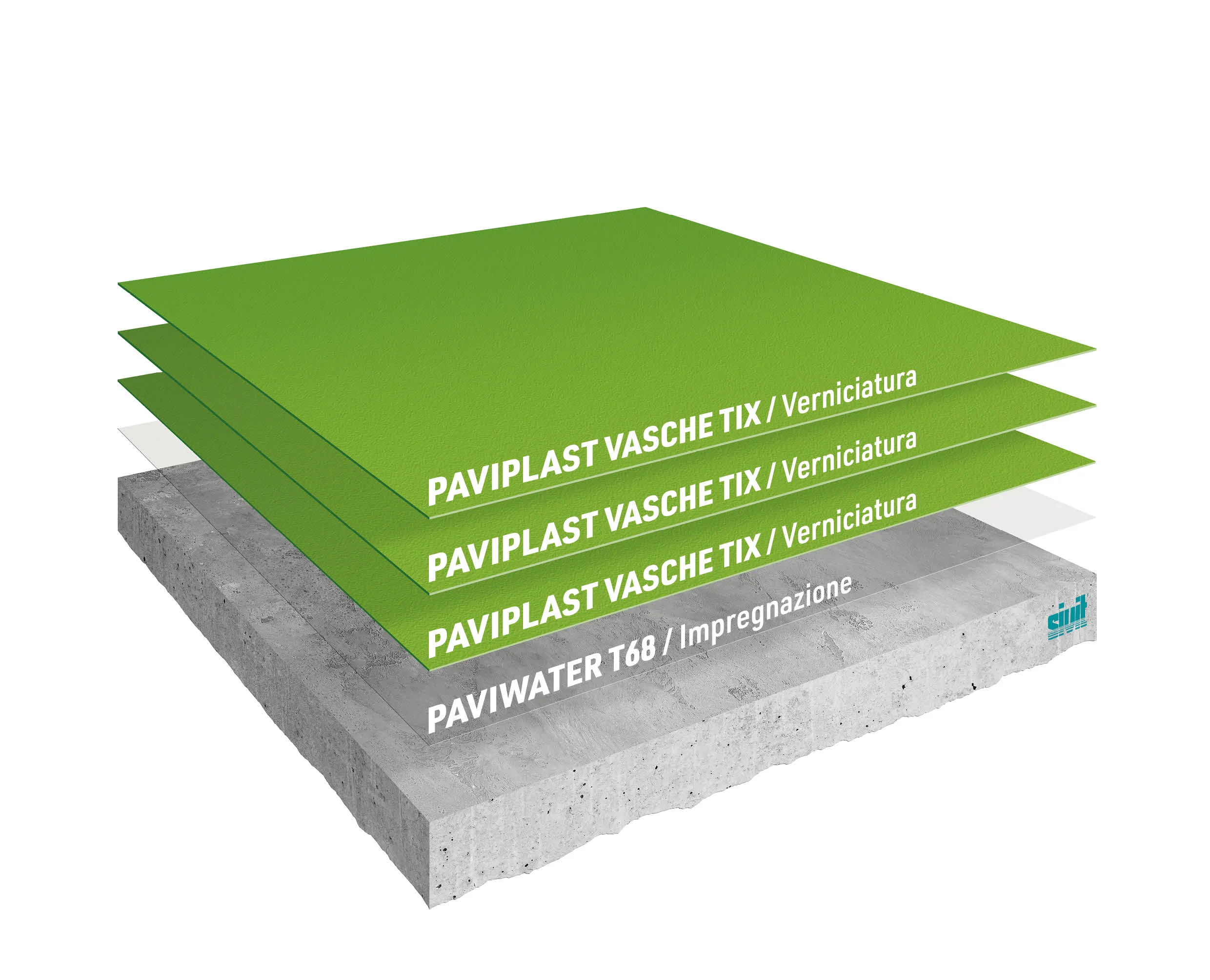

Formulato epossidico bicomponente idoneo per realizzare rivestimenti continui, ad alto spessore, chimico resistenti, per il contenimento di acque industriali e di raffreddamento.

Tipologia: Rivestimenti Anticorrosivi

Descrizione

Formulato a base di resine epossidiche reticolate con indurenti amminici alifatici e cicloalifatici. Il film solido, grazie ad un’elevata densità di reticolazione, presenta un’ottima resistenza chimica nei confronti di diversi aggressivi chimici (acidi, basi e solventi).

Utilizzi

Rivestimenti continui, ad alto spessore, chimico resistenti, per il contenimento di acque industriali e di raffreddamento.

Supporto

Il sottofondo deve possedere una resistenza minima alla compressione di 25 N/mm2 e a trazione di 1,5 N/mm2.

Preparazione del supporto

Cls. nuovo: il supporto deve essere finito a frattazzo medio-fine e stagionato; deve presentare una superficie liscia, planare, esente da polvere e imperfezioni. Non deve affiorare boiacca di cemento: nel caso dovrà essere rimossa mediante sistemi di pulizia adeguati.

Cls. vecchio: il supporto ammalorato (cavità, fessurazioni, ...) deve essere ripristinato e risanato onde ricostruire planarità e grado di finitura idonei. Il supporto deve presentarsi esente da tracce di olio, grassi e residui di trattamenti precedenti.

Supporti metallici: sabbiare al metallo bianco (SSPC-SP5, Svensk Sa3) prima dell’applicazione di PAVIPLAST VASCHE TIX; nel caso si desideri effettuare un trattamento anticorrosivo dell’acciaio o quando il medesimo (dopo la sabbiatura) non possa essere immediatamente rivestito con il PAVIPLAST VASCHE TIX, si dovrà eseguire una sabbiatura al metallo quasi bianco (SSPC-SP10, Svensk Sa2 1/2) e poi applicare a pennello uno strato di primer anticorrosivo.

Applicazione

Al momento dell’applicazione unire i due componenti in un unico recipiente e miscelare con cura con adeguata attrezzatura. Utilizzare rapidamente l’intero contenuto. Nello svuotare il contenitore evitare di raschiare i bordi ed il fondo, in quanto potrebbe esserci del prodotto non perfettamente amalgamato. Per applicazione a rullo, è possibile diluire con Solvente UNI; non superare il 5% sulla quantità di prodotto. Il consumo di prodotto è di circa 300-600 gr/m2.

Avvertenze

I rivestimenti di PAVIPLAST VASCHE TIX esposti alla luce solare possono subire sbiadimenti o variazioni di colore con viraggio verso il giallo; questo fatto non pregiudica in alcun modo le prestazioni del rivestimento.

Tra diversi lotti produttivi dello stesso colore ci possono essere leggere differenze: quando possibile utilizzare materiale proveniente dallo stesso lotto di produzione.

Per applicazioni a bassa temperatura si può scaldare il materiale a 25°C per facilitarne l’applicazione e la catalisi (diminuzione viscosità). Tonalità sul giallo, arancione o alcuni rossi possono richiedere più riprese per ottenere un buon effetto coprente.

Prodotto ad uso professionale, l’acquirente si impegna a seguire tassativamente le avvertenze sopra riportate nell’applicazione del prodotto acquistato e le indicazioni della scheda di sicurezza.

Specifiche tecniche

| DATI PRODOTTO | |

|---|---|

| Colore | RAL 7038 o a richiesta, per lotti minimi di 200 kg |

| Peso specifico (a 25°C) | miscela (A+B): 1,50 +/- 0,05 g/ml |

| Viscosità (a 25°C) | miscela (A+B): 5.000 +/- 1.000 mPa (spindle 2, rpm 6) |

| Residuo secco (A+B) | 95% in peso |

| Punto di infiammabilità | >100°C |

| Solvente per la pulizia attrezzi | Solvente UNI |

| Magazzinaggio | 12 mesi, conservare in luogo asciutto ad una temperatura compresa tra i 5°C ed i 35°C |

| DATI APPLICAZIONE E TEMPI | |

|---|---|

| Rapporto di miscela | in peso: A=100, B=19 |

| Pot-life (50% U.R.) | a 15°C > 6 ore a 25°C 17 min a 30°C > 10 min |

| Secco al tatto (50% U.R.) | a 15°C 10-12 ore a 25°C 2-3 ore (per bassi spessori) a 30°C 1-2 ore |

| Ricopertura (50% U.R.) | a25°C da 6 a 24 ore |

| Condizioni ambientali d’uso | Temperature comprese tra i +15°C e i +30°C, U.R. < 50% e umidità del supporto < 4% PAVIPLAST VASCHE TIX applicato a temperature del supporto inferiori ai 15°C potrebbe macchiarsi a contatto con l’acqua o con preparati a base acquosa e formare macchie biancastre. Tale difetto di resistenza chimica è causato da una reticolazione incompleta. Pertanto, PAVIPLAST VASCHE TIX va applicato ad una temperatura del supporto non inferiore a 15°C e di almeno 3°C superiore alla temperatura di condensa. |

| Manutenzione rivestimento | Per le operazioni di pulizia utilizzare detergenti neutri |

| DATI TECNICI PRESTAZIONALI | |

|---|---|

| Aspetto | Semilucido (film essicato) |

| Durezza (ASTM D 2240) | 80 Shore D |

| Adesione al calcestruzzo | > 2,5 MPascal, con rottura coesiva del supporto |

| Resistenze chimiche | Ottima resistenza nei confronti di vari aggressivi (consultare il nostro Servizio Tecnico) |